+86-13516964051

+86-13516964051

In recent years, Gravity Casting has gained significant traction within various manufacturing sectors. Industry expert Dr. James Anderson remarked, "Gravity Casting offers unmatched precision and cost-effectiveness in metal shaping." This technique allows for intricate designs while maintaining material integrity.

However, challenges remain in adapting to new technologies. Many companies still rely on outdated methods that hinder innovation. The evolving demands of industries mean that utilizing advanced Gravity Casting techniques is necessary for staying competitive. Emerging trends may include enhanced materials and smarter automation systems.

This discussion will explore the 2026 trends in Gravity Casting. The focus will be on refining processes, ensuring sustainability, and implementing smart technology. Companies must confront the imperfections in their existing systems to fully leverage the potential of Gravity Casting.

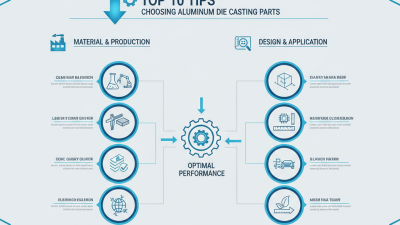

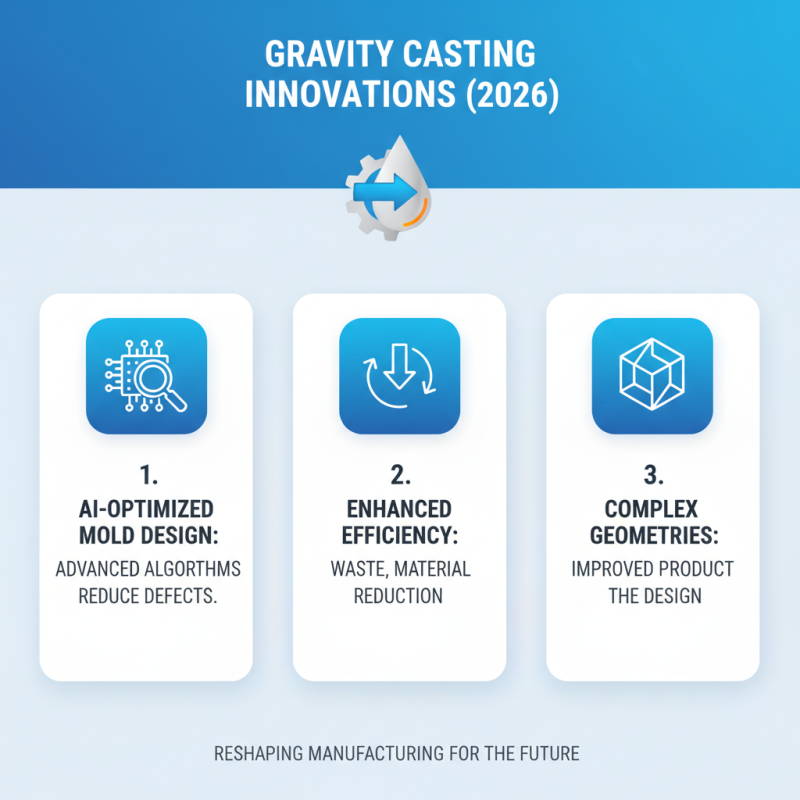

Emerging technologies are reshaping gravity casting techniques as we approach 2026. New innovative methods focus on reducing defects. Advanced algorithms optimize the mold design, enhancing efficiency. This helps manufacturers reduce waste during the casting process. Molds can now feature complex geometries, improving the overall product design.

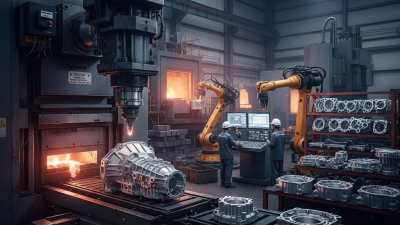

Automation is another significant trend in gravity casting. Robotic systems assist with precision, improving consistency. These systems can quickly adapt to different production needs. They reduce human error, making the process more reliable. Companies must remain aware of the ongoing technological changes. It’s essential to train staff accordingly.

Tip: Regularly evaluate your current equipment. Investing in newer technology can yield significant efficiency gains. Also, consider collaborating with tech innovators. This approach can foster creative solutions. Experimenting with new materials can also yield interesting results. Be open to adapting your practices. Flexibility is key in a fast-evolving industry.

Gravity casting is evolving. Innovative materials are changing the landscape in 2026. Lightweight alloys and composites lead the way. According to industry reports, the use of magnesium and aluminum alloys has increased by 30% in recent years. These materials offer improved strength-to-weight ratios. They also have superior casting properties.

Modern gravity casting techniques now incorporate new materials like carbon fiber. This integration enhances structural integrity while reducing overall weight. A recent study showed that parts made with these composites can be 40% lighter. However, challenges remain. The manufacturing process can be complicated and costly. Not every facility is equipped to handle these materials effectively.

Sustainability is another key focus. Recycled metals are gaining traction, particularly in industries prioritizing environmental impact. Reports indicate that utilizing recycled aluminum can lower energy consumption by up to 95%. However, the quality of recycled materials can vary. This inconsistency poses a challenge for manufacturers. As technology advances, addressing these shortcomings will be vital for the future of gravity casting.

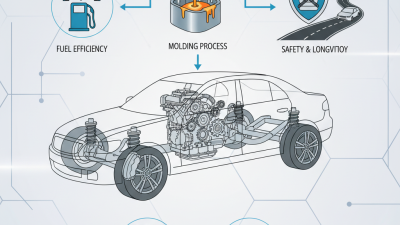

In 2026, gravity casting techniques continue evolving across various industries. This method has proven effective in producing complex shapes with high precision. Industries such as automotive and aerospace are increasingly adopting gravity casting due to its efficiency. Reports indicate that the automotive sector's reliance on gravity casting is expected to rise by 15% over the next few years. This growth reflects the trend toward lightweight materials that enhance fuel efficiency.

Applications of gravity casting extend beyond automotive. The electronics industry utilizes this technique for creating durable housings for devices. These components benefit from the uniformity and strength achieved through gravity casting. By 2026, the electronics market's use of gravity casting is anticipated to increase sharply, driven by demand for high-performance products. However, there are challenges. The initial costs can be substantial. Businesses must weigh long-term benefits against upfront investments carefully.

In construction, gravity casting is finding new avenues. Developers utilize this technique for producing intricate architectural elements. These components enhance aesthetic appeal while maintaining structural integrity. Despite the advantages, some companies struggle with process consistency. Ensuring the quality of each casting is vital for success in demanding sectors. Embracing innovation while addressing these challenges will be key for industry leaders in the coming years.

Sustainability is transforming gravity casting in manufacturing. As industries prioritize eco-friendly practices, gravity casting techniques evolve. This shift meets growing consumer demand for green products. A recent report by the International Casting Association indicates that sustainable materials can reduce carbon emissions by up to 30%.

One exciting trend is the use of recycled metal. Companies now incorporate reclaimed aluminum and other alloys. This practice not only conserves resources but also cuts costs. Some manufacturers have reported up to a 15% decrease in production expenses. However, the challenge lies in sourcing high-quality recycled materials. Not all recycled metals meet stringent performance standards.

Tips: Always evaluate the quality of recycled materials before use. Consider partnering with suppliers who prioritize sustainability.

Moreover, advancements in energy-efficient technologies are crucial. Gravity casting processes are adapting to use less energy while maintaining quality. Implementing modern heat recovery systems can improve efficiency by as much as 25%. Yet, many manufacturers still cling to outdated methods. This reluctance can hinder progress in implementing greener practices.

Tips: Regularly assess your production techniques for potential upgrades. Employee training on sustainable practices can also foster innovation.

This chart illustrates the adoption rates of the top trends in gravity casting techniques expected in 2026. Key areas of focus include sustainable materials and automation, highlighting the industry's shift towards increased efficiency and environmental responsibility.

Gravity casting faces several challenges as it evolves. One main issue is achieving

uniform material flow.

Variations can lead to defects in the final product. Controlling the temperature of the

molten metal also remains a struggle. Inconsistent temperatures can cause

shrinkage or porosity.

Another challenge is the

surface finish quality. Achieving

a smooth surface without the need for additional processing is often difficult. Operators

frequently need to refine their techniques. Moreover,

environmental concerns are

rising. The industry must explore sustainable practices to minimize waste and emissions.

Innovative solutions are emerging. Advanced modeling techniques help predict issues

before casting. Materials science is also progressing. New alloys can improve

strength and

ductility. There is hope these

advancements will ultimately lead to better outcomes in gravity casting for

2026.