+86-13516964051

+86-13516964051

Choosing the right Aluminum Die Casting Parts is crucial for manufacturers. In 2022, the global aluminum die casting market was valued at approximately $14 billion. This figure is expected to grow annually by 5.5% from 2023 to 2030. The flexibility and strength of aluminum make these parts essential in various sectors, including automotive and electronics.

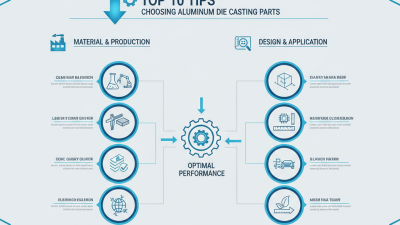

When selecting Aluminum Die Casting Parts, many considerations come into play. Cost is often a primary concern. Many companies struggle to balance quality and expenditure. Additionally, specific performance metrics, such as tensile strength and durability, must be evaluated. Without a clear understanding, manufacturers can end up costly errors in their production.

Some businesses overlook supplier capabilities. A reliable supplier can ensure part consistency. Inadequate research may lead to sourcing inferior materials. An effective selection process not only enhances product reliability but can also significantly reduce long-term costs. Understanding these nuances is vital for making informed decisions.

Aluminum die casting is a process where molten aluminum fills a mold. Understanding this process is crucial for selecting the right parts. Early involvement in design helps avoid issues. It can lead to better quality and reduced costs. Small design changes can significantly improve the outcome.

Several factors influence the effectiveness of die casting. Weight, thickness, and surface finish are vital. A thicker part may be stronger but harder to manufacture. An intricate design might look appealing, yet it complicates production. Thus, a balance must be struck between aesthetics and manufacturability.

Testing is another key aspect. Prototype casting allows for evaluation before mass production. Identifying defects early can save time and resources. While aluminum offers numerous advantages, such as lightweight and corrosion resistance, challenges exist. Continuous improvement and feedback are necessary in this evolving field. The journey of mastering aluminum die casting is ongoing. It requires reflection and adjustment to meet project goals.

When selecting aluminum die casting parts, several key factors require careful consideration. The application of these parts plays a significant role in determining specific requirements. For example, parts used in automotive applications will have different strength and weight considerations than those used in consumer electronics. Understanding the end-use environment is crucial. High-temperature resistance may be necessary, or perhaps, corrosion resistance.

Another important detail is the surface finish of the parts. A smooth finish may be desired for aesthetic reasons, while a rougher texture might enhance grip and functionality. It’s essential to communicate these needs clearly and effectively. Sometimes, you might overlook minor details, resulting in parts that do not meet expectations.

Quality assurance is a critical factor too. Assessing the manufacturing process is vital in ensuring consistency. Look for companies that can provide transparent quality checks throughout production. Missing this aspect can lead to costly mistakes down the line. Ultimately, balancing cost and quality is an ongoing challenge. Aiming for the best often means accepting some imperfections along the way.

When selecting aluminum die casting components, quality standards play a crucial role. The right materials can significantly impact the performance and durability of parts. Look for components that meet industry-specific certifications. These certifications ensure that the parts can withstand required stress and temperature changes.

One common challenge in evaluating these standards lies in the testing methods. Different manufacturers may use varied approaches. This variation can lead to inconsistencies in product quality. It’s essential to understand the processes that each supplier employs. Ask for detailed reports on their quality assurance measures. Without this information, it may be difficult to make an informed choice.

Visual inspection is another critical part of quality evaluation. Inspect for surface defects and dimensional accuracy. Even small flaws can affect functionality. Consider using gauges for precision measurement. This attention to detail helps in ensuring long-term reliability of the components. It’s often in these small details that significant issues can arise if overlooked.

Aluminum die casting is widely used in various industries due to its versatility and efficiency. In automotive manufacturing, for instance, it plays a critical role in producing lightweight components. According to industry reports, approximately 80% of all vehicle parts can be die-cast from aluminum. This not only enhances fuel efficiency but also supports emission reduction goals. The ability to create complex shapes with high precision makes aluminum ideal for engine blocks and structural components.

In the electronics sector, aluminum die casting is crucial for creating heat sinks and enclosures. These components require excellent thermal conductivity and strength. With the market projected to grow by 6% annually, companies are increasingly adopting aluminum die-cast parts. Yet, designers often face challenges in thermal management and fitting different components together. The need for continuous improvement in design and manufacturing processes is evident, highlighting a potential gap in current practices.

The aerospace industry also benefits from this casting method. Lightweight aluminum parts are essential for enhancing aircraft performance and reducing operational costs. Reports indicate that aluminum’s weight-saving potential can lead to up to a 10% reduction in fuel consumption. However, the need for stringent quality checks remains. Failure to achieve structural integrity can result in costly recalls and serious safety concerns. Thus, the challenges of maintaining quality while pursuing innovation must be addressed.

Aluminum die casting is gaining traction due to its cost-effectiveness and sustainability. According to a report by Grand View Research, the global aluminum die casting market is expected to reach $56 billion by 2025. This growth signifies a growing interest in aluminum parts over traditional materials.

One crucial factor in choosing aluminum die casting parts is their recyclability. Aluminum can be recycled multiple times without loss of quality. The recycling process consumes 95% less energy compared to producing new aluminum. This efficiency enhances sustainability, making it an attractive option for manufacturers.

However, businesses often overlook the importance of sourcing and supplier selection. Not all aluminum is created equal. Some suppliers may not adhere to environmental standards. This oversight can lead to hidden costs, causing more damage than good. Failing to consider the entire lifecycle of the product can diminish the overall sustainability of the operation. Therefore, informed choices are essential for long-term benefits.