+86-13516964051

+86-13516964051

The Aluminum Alloy Die Casting industry is evolving rapidly. According to a recent report by MarketsandMarkets, the global aluminum die casting market is expected to reach $6.1 billion by 2026. This growth is driven by increasing demand in automotive, aerospace, and consumer electronics sectors. Choosing the best aluminum alloy die casting process can significantly impact manufacturing efficiency and product quality.

Expert Paul Johnson, a recognized leader in aluminum die casting, emphasizes the importance of selection. He once stated, "Selecting the right alloy and process can enhance performance while reducing costs." Understanding different alloy properties is essential. Some alloys offer excellent fluidity and strength, while others provide lightweight benefits.

An informed approach to aluminum alloy die casting can lead to enhanced productivity. However, many companies overlook the importance of this choice. They may prioritize cost over quality, leading to subpar products. Making poorly informed decisions now could result in future rework or product failures. Reflection on these choices will contribute to sustainable practices in the industry.

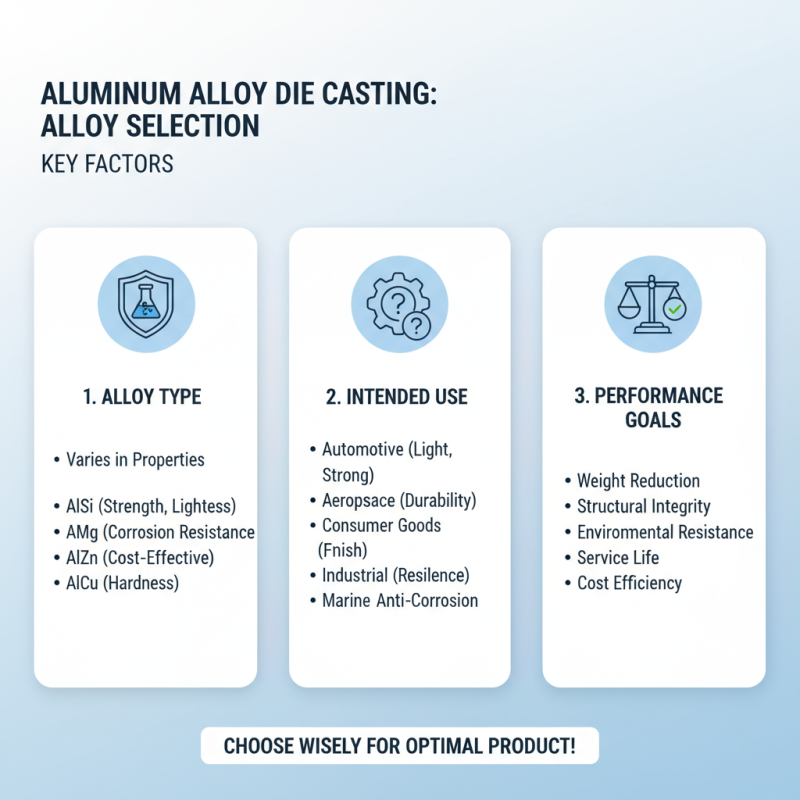

When selecting aluminum alloys for die casting, understanding their types and properties is crucial. Aluminum alloys typically fall into two categories: wrought and cast. Wrought alloys are usually stronger, while cast alloys are more versatile and easier to shape. Some common cast aluminum alloys include 319, 356, and 380. Each has unique characteristics suited for various applications.

Tips: Consider the application’s environment. This determines which alloy will perform best. For instance, if corrosion resistance is crucial, look into alloy 356. It offers good ductility and strength.

Properties of these alloys also vary. For example, alloy 380 is known for its excellent fluidity, making it ideal for complex shapes. However, beware that it can be brittle. Understanding these nuances is essential for making informed choices.

Tips: Test small batches before full-scale production. This helps identify potential issues. Take the time to analyze performance under actual use conditions. Small adjustments can lead to significant improvements in quality and durability. It's a process of trial and reflection.

| Alloy Type | Main Properties | Common Applications | Casting Process Suitability |

|---|---|---|---|

| A356 | Good corrosion resistance, high strength | Automotive parts, Aerospace components | High Pressure Die Casting, Gravity Die Casting |

| A380 | Excellent fluidity, low shrinkage | Electrical housings, Engine parts | High Pressure Die Casting |

| A383 | Good machinability, wear resistance | Consumer electronics, Structural components | High Pressure Die Casting, Gravity Die Casting |

| A390 | Very high wear resistance, low thermal expansion | Engine blocks, Transmission cases | High Pressure Die Casting |

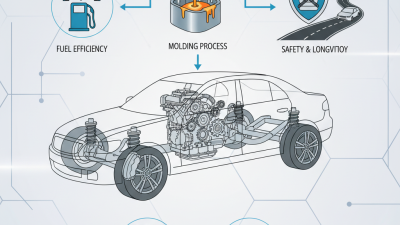

Choosing the right aluminum alloy die casting process requires careful consideration of several key factors. The first factor is the type of aluminum alloy used. Alloys differ significantly in their properties. Some are lighter and stronger, while others may offer better corrosion resistance. Understanding these differences is vital for ensuring the final product meets its intended use.

Another important factor is the casting method itself. High-pressure die casting is common for mass production. It offers precision and surface quality. However, it may not be ideal for small quantities. On the other hand, sand casting can be cost-effective for low-volume needs. Each method has its advantages and disadvantages, depending on the project's demands.

Design complexity also plays a crucial role. Intricate designs can be difficult to achieve through certain methods. It’s essential to evaluate whether the chosen process can accommodate the specific design requirements. Reflection on the challenges faced during production can lead to improvements. Manufacturers should continuously assess their processes for efficiency, quality, and adaptability.

Evaluating production volume needs is a crucial step in selecting the best aluminum alloy die casting process. High-volume production often requires efficient techniques. According to a report by Grand View Research, the global die casting market is expected to reach USD 83.44 billion by 2025. This indicates a rising demand for effective die casting solutions.

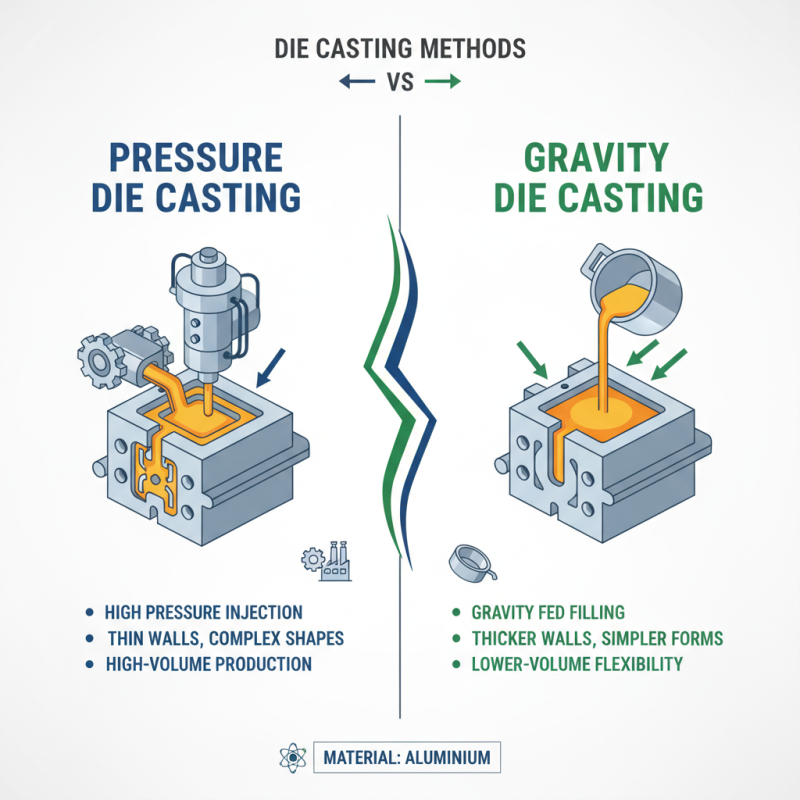

For low to medium production volumes, gravity die casting may be sufficient. It is cost-effective for small batches. However, for high production needs, pressure die casting excels. Pressure die casting can achieve cycle times of 15 seconds or less. This efficiency is essential when meeting tight deadlines. But it’s important to consider the initial setup costs, which can be significant.

Different alloys also influence the choice of process. Certain alloys perform better under specific conditions. Research shows that A380 aluminum is widely used due to its excellent mechanical properties. However, it may not be suitable for all applications. Understanding the specific requirements of each project helps to avoid errors in material selection. Careful analysis ensures that the right process aligns with volume needs and budget constraints.

When selecting a die casting method, understand the differences between pressure and gravity die casting. Pressure die casting uses high pressure to inject molten aluminum into the mold. This method allows for intricate designs and thin-walled sections. It’s ideal for high-volume production runs. However, it can be more expensive and requires precise machinery.

On the other hand, gravity die casting relies on the force of gravity. The molten metal flows into the mold without additional pressure. This method is generally easier and cheaper. But it may not provide the same level of detail as pressure die casting. It’s suited for larger, simpler components, often used in lower-volume production.

**Here are a few tips:**

Consider the part complexity. If your design requires tight tolerances, pressure die casting is likely the better choice. Think about your budget too. Gravity die casting might be more cost-effective for simpler parts. Remember to assess the expected production volumes. The method you choose can impact both lead times and costs significantly. Be mindful of your long-term needs. Analyzing these factors will help you make an informed decision.

When evaluating aluminum die casting processes, cost efficiency is a critical factor. The average cost of aluminum die casting can range from $5 to $25 per pound, depending on several variables. For projects with high-volume needs, this cost can decrease significantly. According to industry reports, high-pressure die casting offers a 30% reduction in production costs compared to other methods. This reduction is pivotal for companies aiming to maximize their ROI.

The efficiency of the process also hinges on the choice of alloy. Certain aluminum alloys can enhance the overall quality of finished products. For example, alloy 383 is favored for its excellent fluidity, which reduces waste and boosts efficiency. However, its price can be higher. A study revealed that using the right alloy can improve casting yields by up to 20%. Yet, production challenges persist. Manufacturers often face issues like air entrapment and mold wear, which can drive costs up unexpectedly.

Balancing cost and quality in aluminum die casting is tricky. While a cheaper process may save funds upfront, it can lead to greater expenses later. The need for careful planning and selection is essential. With an increasing focus on sustainability, exploring innovative alloys could help reduce waste and lower expenses. The industry is in a state of flux, and continuous improvement is necessary.