+86-13516964051

+86-13516964051

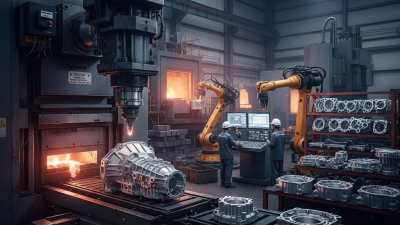

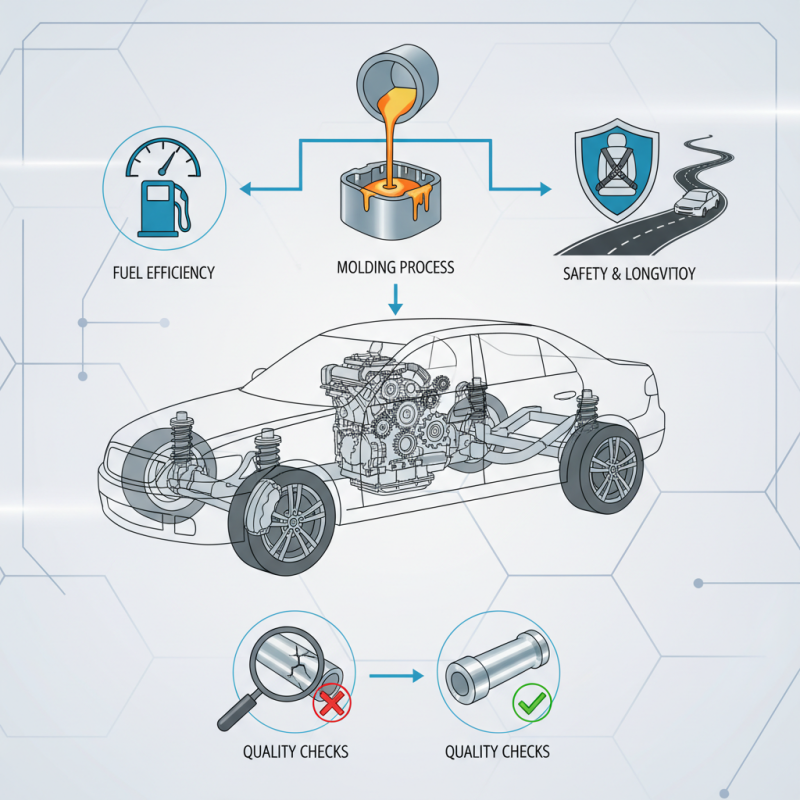

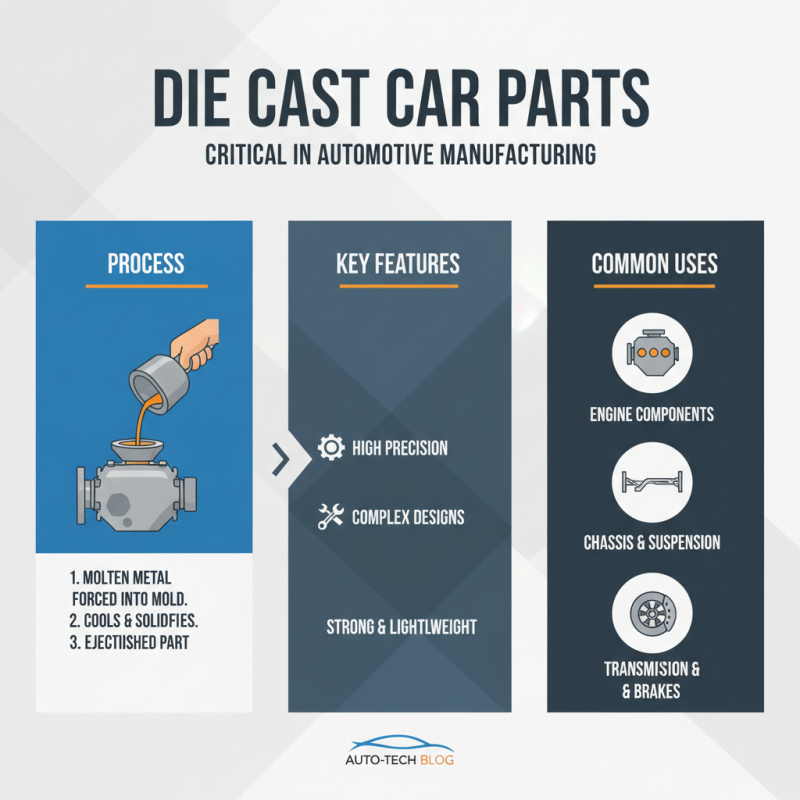

Die Cast Car Parts play a vital role in the automotive industry. These components are created by pouring molten metal into molds. This process results in precise, durable parts essential for vehicle assembly. The accuracy of die casting ensures that each part fits perfectly. This precision reduces time and minimizes errors during production.

Additionally, Die Cast Car Parts contribute to the overall performance of vehicles. Their strength and weight balance improve fuel efficiency. However, not every part manufactured is flawless. Sometimes, defects can occur in the casting process. These issues reflect the need for continuous quality checks. Manufacturers must remain vigilant to ensure high standards.

Moreover, the importance of Die Cast Car Parts goes beyond mere production. They impact vehicle safety and longevity. A faulty part could lead to significant problems down the road. Thus, investing time in quality assurance is crucial. The stakes are high, and every detail matters in creating reliable car parts.

Die cast car parts are crucial components in the automotive industry. They are created through a manufacturing process where molten metal is injected into a mold. This process allows for high precision and complex shapes. According to a report by MarketsandMarkets, the global die-casting market is expected to reach $89.6 billion by 2026, highlighting its significance.

The materials used in die casting often include zinc, aluminum, and magnesium. These metals offer excellent strength-to-weight ratios. A study from the American Foundry Society indicates that die-cast parts can be up to 30% lighter than traditional parts. This reduction in weight can improve fuel efficiency in vehicles.

However, not all die-cast parts measure up to specifications. Quality control is vital in production. Sometimes, the molds wear out quickly, leading to defects. Moreover, the recycling potential of die-cast materials is often underutilized. This raises concerns about sustainability in the automotive sector. Despite these challenges, the importance of die cast car parts remains evident in modern vehicle design and performance.

The die casting process is a fascinating method used to create metal parts. It begins by heating metal until it's molten. This metal is then injected into a mold. The molds can take various shapes. Once cooled, the metal solidifies. This process allows for high precision in manufacturing. However, it requires careful control of temperature and pressure.

The importance of die cast car parts can't be overstated. These parts are lightweight and durable. They help improve vehicle performance and fuel efficiency. Not every design can be achieved easily. Some applications may lead to defects. Pitting or incomplete filling can occur. Skilled operators monitor these issues. Continuous improvement is essential in this industry.

Many manufacturers rely on die casting for production. The process is efficient but has its challenges. It's crucial to balance speed and quality. Proper maintenance of molds is also important. Over time, the wear can affect precision. Innovations are constantly being explored. New materials and techniques emerge to refine this process. The journey to perfect die cast car parts is ongoing.

Die casting has transformed the automotive industry significantly. This process uses high pressure to inject molten metal into a single mold. It allows manufacturers to create intricate shapes with exceptional precision. The resulting parts are often lightweight, which can enhance fuel efficiency.

The advantages of die cast parts are numerous. First, they enable faster production rates compared to traditional methods. This efficiency can lead to cost savings. Furthermore, die-cast components exhibit excellent dimensional accuracy. They minimize the need for additional machining. However, the initial investment in die casting molds can be significant.

Another crucial advantage is durability. Die-cast parts often withstand harsh environments better than other materials. They resist corrosion and wear effectively. Yet, the reliance on specific alloys can limit versatility; not all metals are suitable for die casting. Overall, while there are challenges, the benefits of die cast parts are clear in automotive applications.

| Dimension | Description | Importance in Automotive |

|---|---|---|

| Material Strength | High tensile strength due to precise metal alloy combinations | Increases durability and lifespan of parts |

| Complex Shapes | Ability to create intricate designs and shapes | Enhances aerodynamics and aesthetic appeal |

| Production Efficiency | Faster and more efficient production process | Reduces manufacturing lead time and costs |

| Dimensional Accuracy | Highly accurate dimensions maintained throughout production | Ensures proper fit and function within automotive assemblies |

| Cost-Effectiveness | Lower material waste and reduced labor costs | Makes the overall production more economical |

Die cast car parts play a critical role in the automotive industry. They are produced using a manufacturing process that involves forcing molten metal into molds. This technique allows for high precision and complex designs. As a result, die cast parts are commonly used in various automotive applications, from engine components to chassis parts.

A recent industry report highlighted that die cast parts account for approximately 30% of the total metal components used in vehicles. These parts are favored for their lightweight nature and structural integrity. For example, many high-strength aluminum die cast parts are used for engine blocks and transmission housings. This not only enhances performance but also contributes to fuel efficiency.

However, the reliance on die cast parts is not without challenges. The energy-intensive process can generate significant waste and carbon emissions. Some manufacturers face difficulties in sourcing high-quality recyclable materials. Despite these concerns, the demand for die cast components continues to grow. Automakers are looking for innovative solutions to mitigate environmental impacts while maintaining performance standards. The ongoing evolution of die casting technology could play a key role in addressing these issues.

Die cast technology is crucial in the automotive industry. It enhances vehicle performance and durability. The precision of die cast parts ensures better fitting and functionality. These components often contribute to weight reduction. This reduction leads to improved fuel efficiency and handling.

Tips: Always consider the material during manufacturing. Aluminum and zinc are popular choices. They balance strength and weight effectively. Remember, poor quality die cast parts can lead to failures. Reflection on manufacturing processes is vital. Ensure quality checks are in place.

As vehicles evolve, so does die casting. Innovations are enhancing the technology further. Techniques like hot chamber die casting improve production speed. Yet, not all manufacturers adopt these advancements. They may miss out on the benefits. Regular assessment is important to stay competitive.