+86-13516964051

+86-13516964051

In the realm of modern manufacturing, the importance of precision and efficiency cannot be overstated. Metal Die Casting has emerged as a pivotal technique that not only streamlines production processes but also enhances the quality of metal components. According to industry expert James Harrington, “Metal Die Casting is the backbone of efficient manufacturing, allowing rapid production of complex geometries with exceptional accuracy.” This statement encapsulates the vital role that Metal Die Casting plays in various sectors, including automotive, aerospace, and electronics.

As manufacturers strive to meet the increasing demands for high-quality products at competitive prices, the relevance of Metal Die Casting grows. This advanced process enables the creation of intricate designs that would be challenging or impossible to achieve through traditional manufacturing methods. Furthermore, the use of this technique significantly reduces production time and material waste, ultimately contributing to a more sustainable manufacturing landscape.

In conclusion, understanding the benefits and capabilities of Metal Die Casting is essential for any organization looking to optimize its manufacturing processes. By harnessing the advantages of this innovative technology, companies can not only enhance productivity but also maintain a competitive edge in an ever-evolving market.

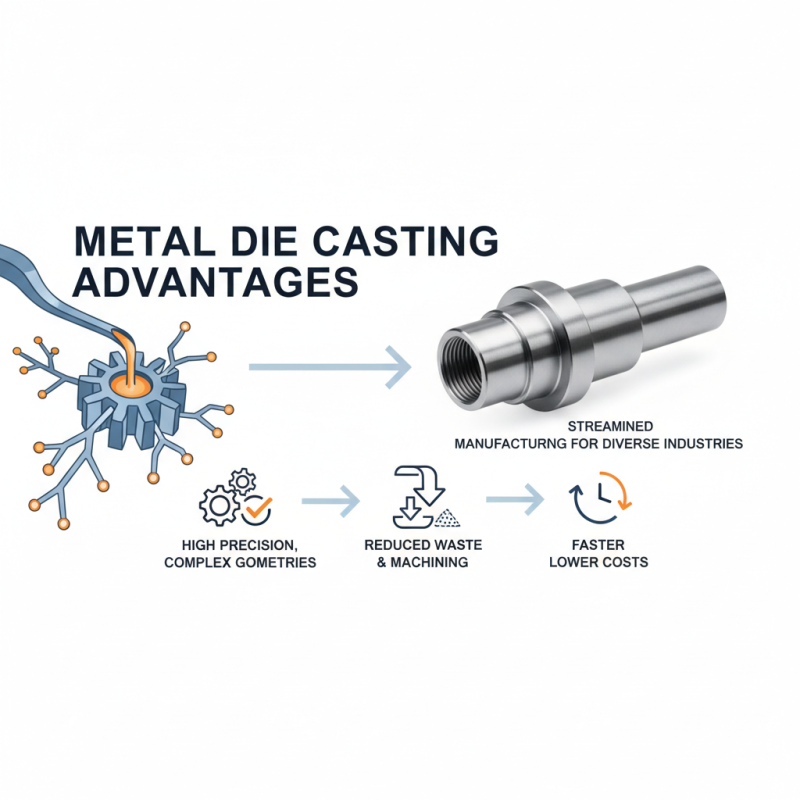

Metal die casting is a pivotal manufacturing process that allows for the production of intricate metal components with exceptional precision and efficiency. It involves forcing molten metal into a mold cavity under high pressure, resulting in highly detailed parts that often require minimal finishing. This technique is particularly advantageous for high-volume production runs, as it significantly reduces waste and optimizes material usage. The reproducibility and consistency of die casting make it an ideal choice for industries ranging from automotive to electronics.

The process of metal die casting not only enhances productivity but also enables manufacturers to achieve complex geometries that may not be feasible with other fabrication methods. By utilizing advanced technology and automated systems, manufacturers can streamline their operations, reduce cycle times, and lower costs. Additionally, the ability to use a variety of alloys expands the range of applications, catering to the specific needs of different sectors. The integration of metal die casting in manufacturing processes ultimately leads to faster turnaround times and improved overall quality of end products.

Metal die casting is a manufacturing process that brings significant advantages to production efficiency, making it an essential choice for various industries. One of the primary benefits of metal die casting is its ability to produce complex geometries with high precision. This precision reduces the need for extensive machining, minimizing waste and decreasing production times. By creating intricate shapes in a single operation, manufacturers can streamline their processes, resulting in faster turnaround times and reduced labor costs.

Another key benefit of metal die casting is the consistency it offers in mass production. Once the die is created, it can be used repeatedly to produce identical parts with minimal variation. This repeatability not only ensures quality control but also enhances the scalability of manufacturing operations. As production demands increase, companies can easily scale up their output without compromising on product quality. Additionally, metal die casting allows for the use of a wide range of alloys, contributing to the durability and strength of the final products, making it a reliable choice for applications that require robust materials.

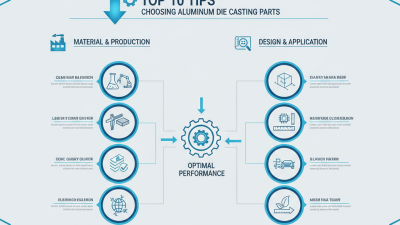

Die casting is a highly efficient manufacturing process utilized to produce complex metal parts with precision. The materials chosen for die casting play an integral role in determining both the quality and performance of the finished product. Commonly, aluminum, zinc, and magnesium are the preferred metals due to their excellent fluidity, strength, and lighter weight. Aluminum, for instance, is favored for its corrosion resistance and ability to be molded into intricate shapes, making it ideal for automotive and aerospace applications. Zinc is known for its ability to form thin walls and fine details, which is essential for consumer electronics and hardware components. Magnesium also boasts a high strength-to-weight ratio, making it desirable for lightweight structures in various industries.

When selecting materials for die casting, consider the specific application requirements. For instance, aluminum is suitable for high-temperature environments, while zinc is ideal for applications requiring higher rigidity.

Tip: Always evaluate the thermal and mechanical properties of the metal you choose to ensure it meets the demands of your application. Additionally, factor in the cost-effectiveness of the material against its performance to achieve the best balance for your manufacturing needs.

In recent years, advancements in die casting technology have expanded the possibilities for material usage. Not only have traditional metals remained prevalent, but new alloys are being developed to enhance durability and reduce production costs.

Tip: Stay updated on the latest material trends and innovations in die casting to leverage the best options for your projects and remain competitive in the marketplace.

Die casting techniques are pivotal in modern manufacturing, providing a high-precision solution for creating complex metal components. This method involves forcing molten metal into a mold cavity under high pressure, enabling the production of intricate shapes with superior surface finish and dimensional accuracy. According to the 2021 Global Die Casting Market Report, the industry is expected to grow at a CAGR of 5.1%, reaching $10.5 billion by 2025, driven by increased demand in sectors like automotive and aerospace.

There are several die casting techniques that are widely utilized today, including hot chamber and cold chamber processes. The hot chamber process is particularly efficient for non-ferrous metals like zinc and lead, allowing for fast production rates and reduced operational costs. In contrast, the cold chamber process is suitable for materials such as aluminum and requires the molten metal to be poured into the chamber, making it ideal for high-temperature materials. An estimated 60% of aluminum castings produced globally employ these methods, demonstrating their significance in achieving high-volume production while maintaining quality standards. This adaptability to various applications underscores the vital role of die casting in enhancing manufacturing efficiency across diverse industries.

The field of metal die casting faces several challenges that impact production efficiency, material quality, and cost-effectiveness. One of the primary difficulties is maintaining optimal temperatures during the casting process. Variations in temperature can lead to defects such as porosity and dimensional inaccuracies, which necessitate thorough monitoring and control measures. Additionally, the need for rapid production cycles often conflicts with the quality assurance processes. Striking a balance between speed and the integrity of the final product is essential for manufacturers aiming to meet market demands.

Innovation plays a crucial role in addressing these challenges. Advances in mold design and materials have led to improved thermal conductivity and reduced cycle times. Technologies such as computer-aided design (CAD) and simulation software enable engineers to predict flow patterns and thermal behavior, resulting in enhanced mold production and fewer defects. Furthermore, automated systems and robotics are increasingly integrated into die casting processes, minimizing human error and increasing consistency. The adoption of such technologies not only boosts productivity but also allows for greater flexibility in producing complex geometries, ultimately driving the evolution of manufacturing practices in the metal die casting industry.