+86-13516964051

+86-13516964051

In the ever-evolving landscape of manufacturing, the optimization of metal parts has emerged as a critical focus for engineers and designers seeking to enhance both durability and performance. As industries face increasing demands for efficiency, reliability, and longevity, understanding the intricate relationship between the characteristics of metal parts and their functional applications is paramount. Metal parts serve as the backbone of countless mechanical systems, and their performance directly influences the overall effectiveness of various products.

The quest for optimized metal parts involves a multi-faceted approach that encompasses material selection, advanced processing techniques, and innovative design principles. By leveraging advancements in metallurgy and adopting practices that emphasize precision and resilience, manufacturers can significantly improve the operational lifespan and efficiency of these components. This introduction will explore key strategies for optimizing metal parts, ultimately leading to superior performance and sustainability in modern applications. Through a comprehensive examination of the latest trends and methodologies, we aim to provide insights that empower engineers to make informed decisions in their pursuit of excellence in metal part production.

When optimizing metal parts for enhanced durability and performance, selecting the right materials is paramount. The choice of material significantly impacts the mechanical properties, resistance to wear, and overall longevity of metal components. A thorough understanding of the application demands—such as load, environmental conditions, and temperature variations—is fundamental in guiding this selection process. Engineers often turn to various alloys, each with unique characteristics that can cater to specific performance requirements.

**Tips:** Consider employing finite element analysis (FEA) during the design phase. This allows for simulation of how different materials respond to various stresses and environments, helping you make informed decisions on material selection.

Additionally, it’s essential to assess the manufacturability of the chosen materials. Some metals may offer superior strength or corrosion resistance but can be challenging to fabricate. Understanding the capabilities of your manufacturing processes can prevent unexpected delays and extra costs during production.

**Tips:** Regularly engage with suppliers for insights into material innovations and improvements. Staying abreast of the latest developments can enable you to incorporate advanced materials that enhance performance while maintaining cost-effectiveness.

| Material Type | Tensile Strength (MPa) | Hardness (Rockwell) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|---|---|---|

| Stainless Steel | 520 | 80 | Excellent | 16 | Medical Equipment, Marine Applications |

| Aluminum Alloy | 350 | 75 | Moderate | 205 | Aerospace, Automotive |

| Titanium Alloy | 900 | 36 | Very Good | 15 | Medical Implants, Aerospace |

| Copper | 210 | 30 | Poor | 400 | Electrical Components, Heat Exchangers |

| Nickel Alloy | 650 | 85 | Excellent | 14 | Aerospace, Chemical Processing |

Optimizing metal parts for enhanced durability and performance is crucial in various applications, from automotive to aerospace. One of the most effective methods to achieve this is through advanced surface treatments. These techniques not only improve the physical properties of metal parts but also extend their lifespan, making them more resistant to wear, corrosion, and fatigue.

Incorporating surface treatments such as anodizing, shot peening, or laser surface hardening can significantly enhance the surface characteristics of metal components. Anodizing, for instance, increases resistance to corrosion by creating a protective oxide layer, while shot peening improves fatigue resistance by inducing compressive stress. Laser surface hardening allows for precise control of the hardening process, resulting in improved wear resistance while maintaining the ductility of the underlying metal.

Tips: When selecting a surface treatment, consider the specific operational environment of the metal parts. For parts exposed to harsh chemicals, prioritize treatments that focus on corrosion resistance. Also, regularly assess the performance of treated parts to ensure the chosen surface treatment continues to meet operational demands. Finally, experiments with different combinations of treatments can reveal synergistic effects that further enhance durability and performance.

To enhance the durability of metal components, it is crucial to adopt innovative design strategies that address the inherent weaknesses in metal parts. Research indicates that over 60% of mechanical failures in industries can be attributed to insufficient design considerations. By integrating advanced simulation techniques during the design phase, engineers can predict potential stress points and optimize geometries to mitigate these risks. For instance, implementing topology optimization methods can result in weight reduction without compromising structural integrity, leading to improvements in both performance and lifespan.

Material selection is also pivotal in enhancing the performance of metal components. Studies have shown that choosing high-strength alloys or composites can significantly improve fatigue resistance and corrosion resistance. For example, using materials with a higher tensile strength can increase the endurance limit, essential for applications subjected to cyclic loading. Furthermore, surface treatments such as nitriding or shot peening can enhance the fatigue strength of metal surfaces, providing a protective layer that diminishes wear and tear. These design strategies, supported by ongoing advancements in manufacturing technologies, ultimately lead to more resilient metal parts capable of withstanding challenging operational conditions.

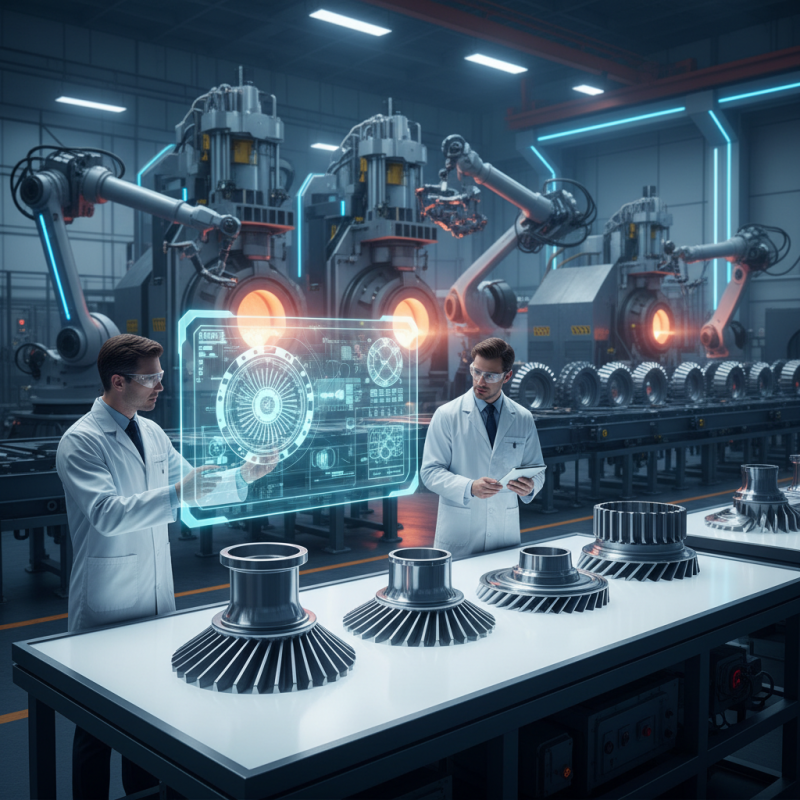

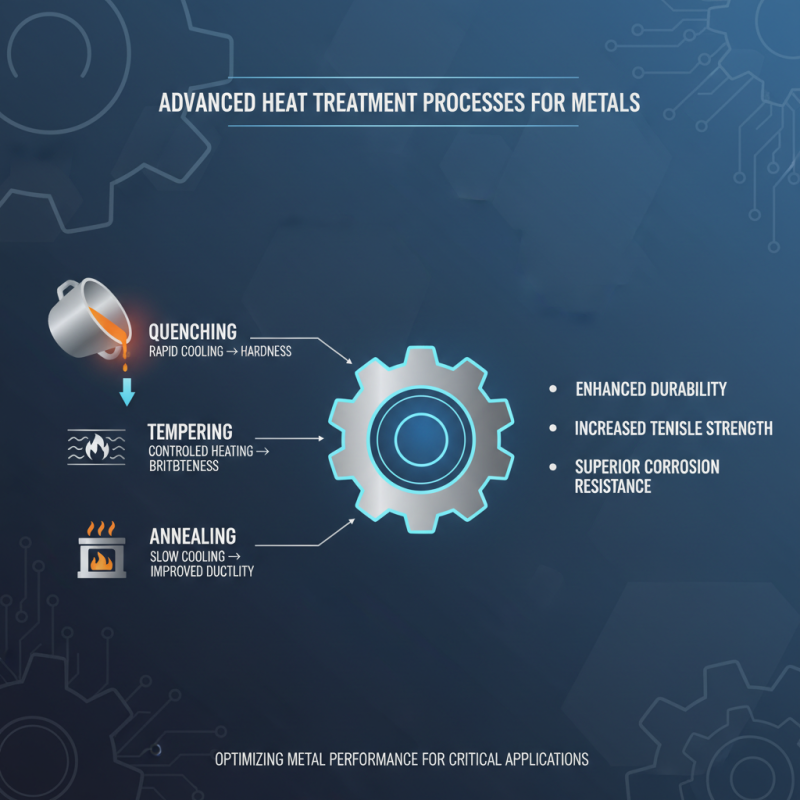

Heat treatment processes are pivotal in enhancing the durability and performance of metal parts, especially in industries that demand high precision and reliability. Innovations in these processes allow manufacturers to manipulate the microstructure of metals, leading to significant improvements in mechanical properties. Techniques such as quenching, tempering, and annealing are continuously being refined to achieve optimal results. These advancements help in reducing brittleness while increasing tensile strength and corrosion resistance, thus extending the lifespan of metal components used in critical applications.

Moreover, the integration of advanced technologies such as computer simulations and real-time monitoring during heat treatment processes has transformed how manufacturers approach optimization. By leveraging data analytics and artificial intelligence, companies can predict how different heat treatment parameters will affect the final properties of the metal parts. This proactive approach not only enhances the efficiency of the heat treatment but also allows for greater customization, enabling manufacturers to meet specific performance requirements while reducing material waste and production times.

Quality control (QC) in metal manufacturing processes is vital for optimizing the durability and performance of metal parts. According to recent industry reports, up to 50% of manufacturing inefficiencies stem from inadequate quality assurance practices, leading to increased scrap rates and rework costs. Implementing systematic QC measures—such as regular inspections, material testing, and process monitoring—can significantly enhance product reliability. For instance, the International Organization for Standardization (ISO) emphasizes that companies adopting robust quality management systems can improve operational efficiency by as much as 30%.

Best practices in QC also include utilizing advanced technologies such as automated inspection systems and data analytics. These tools can identify defects early in the production cycle, reducing the likelihood of compromised parts reaching the market. A study conducted by the American Society of Mechanical Engineers found that organizations employing real-time data analysis are 70% more effective in maintaining product quality standards. Furthermore, adherence to standardized testing protocols, such as ASTM and ASME, ensures that materials meet industry specifications, ultimately leading to improved performance and enhanced durability of the final products.