+86-13516964051

+86-13516964051

Aluminum Cast Parts play a crucial role in many modern industries. They are lightweight and strong, making them ideal for diverse applications. According to a recent market analysis by Grand View Research, the global aluminum casting market is expected to reach nearly $36 billion by 2025. This growth highlights the increasing demand for high-performance materials in sectors such as automotive, aerospace, and electronics.

In the automotive industry alone, aluminum castings are essential for making components like engine blocks and transmission housings. This reduces the overall weight of vehicles, improving fuel efficiency. Additionally, in the aerospace sector, these parts are vital for manufacturing aircraft components, offering exceptional strength-to-weight ratios. However, it is important to examine the challenges in the production processes. The quality control of aluminum cast parts can sometimes be inconsistent, leading to defects and material waste.

Despite the advantages, there are areas requiring attention. The energy consumption during aluminum casting is significant. This raises questions about the environmental impact of production. Companies must innovate to enhance sustainability while meeting industry standards. As industries continue to evolve, the versatility of aluminum cast parts remains undeniable, shaping the future of manufacturing.

Aluminum cast parts play a crucial role in aerospace engineering. They are lightweight yet strong, making them ideal for aircraft structures. Components like brackets, housings, and frames are often made from aluminum. This choice helps improve fuel efficiency. Lightweight materials reduce the aircraft's weight, leading to lower fuel consumption.

One practical application is in engine components. Aluminum castings in engines help manage heat effectively. This property enhances engine performance and longevity. However, there's a risk of mechanical failure if not designed correctly.

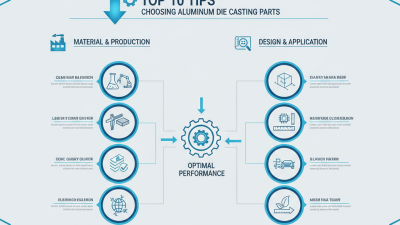

Tips: Always consider the casting process. Ensure proper design for weight distribution. Undercuts and thin sections can complicate the process, leading to defects.

In addition to engines, aluminum parts are used in landing gears and wing structures. Their durability allows for repeated stress cycles without jeopardizing safety. Engineers often face the challenge of balancing strength and weight. It requires constant reflection on design choices. Adjustments may be necessary during development.

Tips: Evaluate material properties continuously. Simulations can reveal potential weaknesses early. Always keep user safety a top priority.

| Application | Description | Benefits | Typical Use Cases |

|---|---|---|---|

| Aircraft Engine Components | Parts like housings and brackets that support the engine. | Lightweight, high strength, and good thermal conductivity. | Commercial and military aircraft engines. |

| Structural Components | Load-bearing parts that form the aircraft structure. | Enhanced durability and reliability under stress. | Airframes and fuselage sections. |

| Landing Gear Parts | Components that provide support during takeoff and landing. | High strength and corrosion resistance. | Aircraft landing gear systems. |

| Fuel System Components | Parts involved in fuel delivery and management. | Improved fuel efficiency and weight reduction. | Tanks, pumps, and lines in aircraft fuel systems. |

| Control Surfaces | Parts that control the aircraft's motion and stability. | Responsive and lightweight for enhanced maneuverability. | Ailerons, rudders, and elevators. |

| Cabin Elements | Interior parts such as seat frames and paneling. | Aesthetic appeal with lightweight properties. | Passenger cabins in commercial aircraft. |

| Heat Exchangers | Components that transfer heat from one medium to another. | Efficient thermal management for overall system performance. | Cooling systems in engines and avionics. |

| Propeller Parts | Elements that contribute to the propulsion of the aircraft. | Optimum weight distribution and strength. | Fixed-pitch and variable-pitch propellers. |

| Safety Equipment | Parts such as firewalls and structural reinforcements. | Enhanced safety and protection for passengers and crew. | Emergency systems and aircraft structure. |

| Electrical Enclosures | Housing for electrical systems and circuitry in aircraft. | Good EMI shielding and thermal properties. | Avionics systems and cockpit electronics. |

Aluminum cast parts play a pivotal role in automotive manufacturing. They are

lightweight yet strong, significantly reducing the overall weight of vehicles. According to industry reports, using aluminum can lower vehicle weight by up to 30%. This weight reduction improves fuel efficiency, which is crucial for meeting regulatory standards and consumer demands.

In recent years, the automotive sector has embraced aluminum for engine components, transmission cases, and structural parts. These applications enhance performance while also meeting environmental regulations. A study showed that lightweight vehicles equipped with aluminum parts lead to a 20% increase in fuel economy. However, companies must continually assess quality to ensure safety, as improper casting can result in defects.

Tips: Always verify supplier certifications. Quality assurance processes are vital for aluminum production. Additionally, regular inspections during manufacturing can prevent costly recalls later. Emphasizing the need for thorough testing helps bolster consumer confidence, even if it requires time and investment. Investing in technology and training can mitigate risks and enhance production quality.

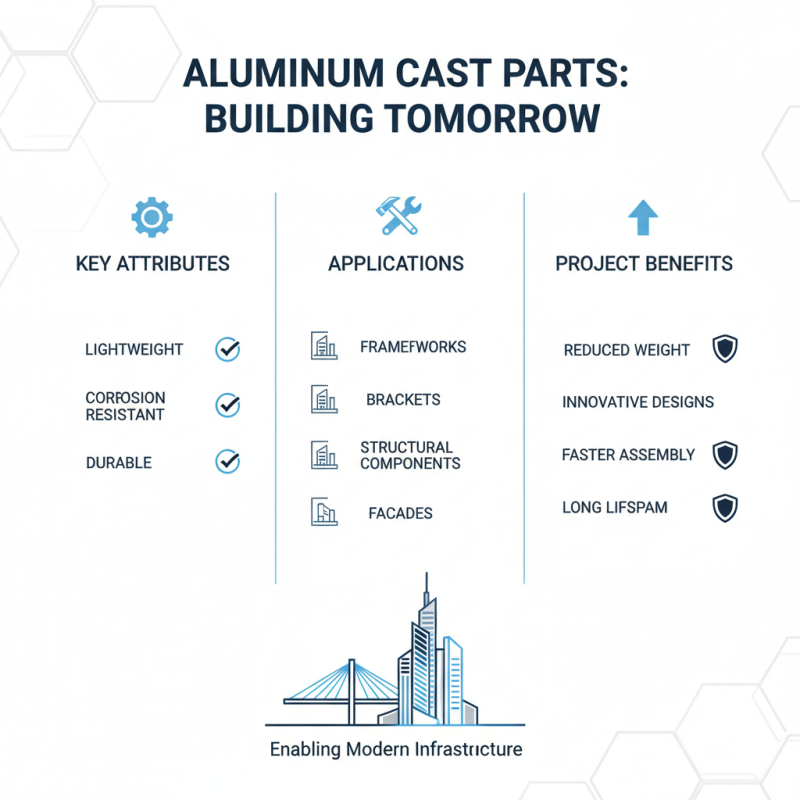

Aluminum cast parts play a vital role in construction and infrastructure. Their lightweight nature makes them ideal for various applications, such as frameworks, brackets, and structural components. Builders appreciate these parts for their corrosion resistance and durability. Using aluminum lowers overall project weight, allowing for innovative designs.

When incorporating aluminum cast items, consider the environmental impact. Aluminum has a high recycling rate, which can help minimize waste. Efficient recycling processes benefit both the environment and the economy. Moreover, ensure proper techniques are used during installation. Improper handling can lead to structural weaknesses over time.

Tips: Always verify the quality of aluminum cast parts before use. This can prevent future issues. Additionally, opt for local suppliers whenever possible. This choice supports regional economies and reduces transportation emissions. These factors contribute to a greener construction future. Balancing innovation and responsibility is essential for sustainable infrastructure development.

Aluminum cast parts are increasingly vital in the electrical and electronics industry. These components offer numerous advantages, making them ideal for various applications. One significant benefit is their lightweight nature. Reports indicate that aluminum cast parts can reduce overall weight by up to 50% compared to steel. This property is crucial for improving energy efficiency. Lighter products consume less power, which is a major concern in today's market.

Corrosion resistance is another key advantage of aluminum. Unlike some metals, aluminum naturally forms a protective oxide layer. This layer prevents oxidation and enhances durability. A study found that aluminum parts can last up to 10 years longer than other materials in harsh environments. However, the casting process must be carefully monitored. Inconsistencies can lead to defects, impacting long-term performance.

Thermal conductivity also plays a role in the electronics sector. Aluminum cast parts can effectively dissipate heat, protecting sensitive components. For high-performance devices, effective heat management is crucial. However, achieving optimal thermal properties requires precise control over the casting process. In some cases, manufacturers face challenges in balancing cost and quality. Despite these hurdles, the advantages clearly outweigh the potential downsides.

This chart illustrates the benefits of aluminum cast parts in various applications within the electrical and electronics industry. The advantages listed below highlight the versatility and effectiveness of aluminum in meeting industry demands.

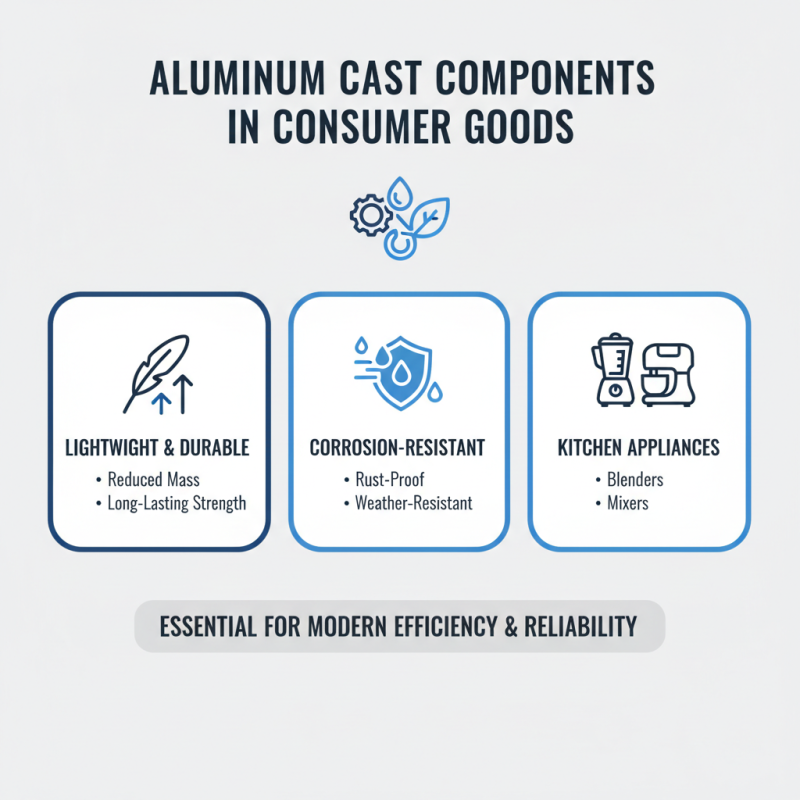

Aluminum cast components play a vital role in consumer goods production. These parts are lightweight, durable, and resistant to corrosion. Their unique properties make them ideal for various applications. For instance, aluminum is often used in the manufacturing of kitchen appliances. Many modern blenders and mixers rely on aluminum cast parts for strength and efficiency.

Despite these advantages, there are challenges in using aluminum. The casting process can be complex. It requires precision to avoid defects. Even minor imperfections can affect product quality. Manufacturers must invest time and resources into quality control. This ensures that the final product meets consumer expectations.

Another issue is cost fluctuations. Prices of aluminum can vary based on market conditions. This unpredictability can impact production budgets. Producers must adapt to maintain profitability. Smaller businesses may struggle with these changes. Their capacity to absorb costs is often limited. The industry must continually innovate to enhance efficiency and reduce waste.