+86-13516964051

+86-13516964051

In the world of manufacturing, selecting the right Metal Casting Equipment is crucial. Expert John Smith, a veteran in the field, states, “Investing in quality equipment streamlines production and enhances outcomes.” Whether you’re new to metal casting or looking to upgrade, understanding your options can be overwhelming. Each piece of equipment plays a specific role in the casting process.

While there are many types of Metal Casting Equipment available, not all serve every production need effectively. Each machine has strengths and weaknesses that require careful consideration. For example, a high-pressure die casting machine excels in precision, while a sand casting setup may offer more flexibility.

As demands for efficiency and quality rise, it’s vital to reflect on the current tools at your disposal. Can the existing equipment keep pace with your production goals? Are there innovative solutions that might enhance productivity? These questions are essential when making informed decisions about Metal Casting Equipment.

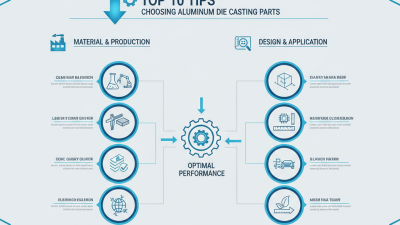

In the metal casting industry, choosing the right equipment is crucial for efficient production. A quality melting furnace is essential, as it ensures that metals are melted uniformly. Proper temperature control improves casting accuracy. Avoid purchasing underpowered furnaces; they often lead to uneven heating and wasted materials.

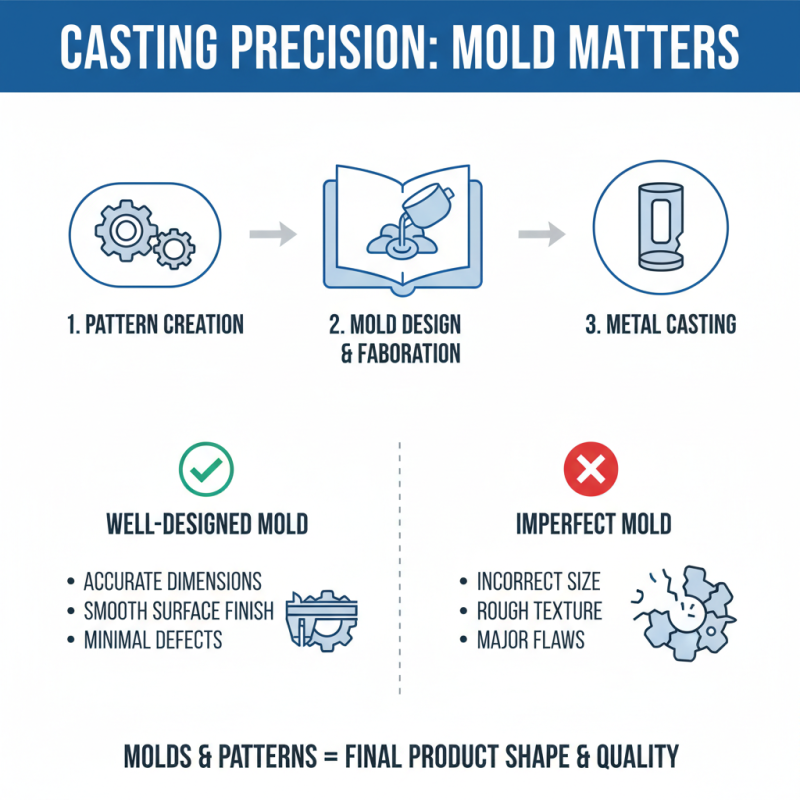

Molds play a vital role in defining the shape and quality of the final product. Investing in high-quality molds can minimize defects. However, be cautious; poorly designed molds can cause misalignment. Regular inspections and maintenance are needed to keep molds in optimal condition.

Tips: Always keep a close eye on your equipment. Over time, wear and tear affect performance. Implement a review system for all machines. This ensures that you catch issues early, preventing major downtime. Use digital tools for monitoring, but don’t ignore frequent physical checks. Balancing high-tech solutions with hands-on procedures yields the best results.

Induction furnaces play a crucial role in modern metal casting processes. They provide consistent heating through electromagnetic induction. This method ensures that metals melt uniformly. Unlike traditional furnaces, induction furnaces can achieve high temperatures quickly. This efficiency is vital when working with various alloys. They also reduce energy consumption, which helps manage production costs.

The operation of induction furnaces is not without challenges. Some operators may struggle with temperature control. Accurate monitoring is essential for quality. Every alloy has a specific melting point. Small deviations can affect the final product. It requires skilled personnel to adjust settings on the fly. Furthermore, the initial investment can be daunting for smaller operations. Balancing costs with benefits is a common concern in the industry.

Despite these imperfections, the advantages are clear. Induction furnaces are adaptable and can serve diverse production needs. They support different metal types, including ferrous and non-ferrous metals. This flexibility is attractive to many manufacturers. However, one must constantly evaluate their effectiveness. Regular maintenance is necessary to ensure they function optimally. Each casting project demands careful consideration of all variables.

The casting process highly relies on molds and patterns. These components dictate the final shape and dimensions of the metal products. A well-designed mold ensures precision. However, even slight imperfections in the mold can lead to defects in the final casting.

Patterns are equally crucial. They determine how the molten metal flows and fills the cavities. Inaccurate patterns can cause air traps or uneven surfaces. These flaws can affect the performance of the final product. Checking and maintaining patterns is vital for quality control. Regular inspections can identify wear and tear, but not all issues are visible at first glance.

While advanced technology aids in mold making, human oversight remains important. A rushed job can introduce errors. Each step requires attention to detail. This includes considering the cooling rate of the metal. Unpredictable cooling can warp the final piece. Regular training for staff in these areas is essential for consistent quality.

When considering metal casting equipment, the choice of casting machines is crucial. Different types serve varied production needs. For instance, sand casting machines are widely used due to their versatility. Reports indicate that sand casting accounts for over 60% of the metal casting market. This method is effective for complex shapes and large production runs, but it may lack precision compared to other methods.

Investment casting is another option. It allows for high detail and smooth finishes. However, it requires a longer lead time, which can be a drawback. Studies show that 30% of production managers cite lead time as a critical factor in their decision-making process. Die casting is known for its speed. This method utilizes high pressure to inject molten metal, making it efficient for mass production. Yet, it presents challenges in terms of initial setup costs. This can deter smaller manufacturers.

Moreover, the environmental impact of each method can't be overlooked. Some casting methods produce a significant amount of waste. Reports highlight that approximately 20% of foundry waste is recyclable, emphasizing the need for sustainable practices. Many manufacturers are still refining their processes. There is room for improvement in reducing waste and enhancing energy efficiency. Balancing these factors will be key in future advancements in metal casting technology.

| Equipment Type | Casting Method | Production Speed (units/hour) | Maximum Weight Capacity (kg) | Typical Applications |

|---|---|---|---|---|

| Die Casting Machine | Pressure Die Casting | 300 | 600 | Automotive Parts, Electronics |

| Sand Casting Machine | Green Sand Casting | 50 | 1000 | General Metal Parts, Machinery Components |

| Investment Casting Machine | Lost Wax Casting | 20 | 200 | Aerospace, Medical Devices |

| Centrifugal Casting Machine | Centrifugal Casting | 15 | 300 | Pipes, Tubes, Cylinders |

| Continuous Casting Machine | Continuous Casting | 80 | 500 | Steel, Copper, Aluminum Products |

| Low-Pressure Casting Machine | Low-Pressure Casting | 60 | 300 | Automotive, Industrial Applications |

| Permanent Mold Casting Machine | Gravity Casting | 100 | 200 | Lightweight Parts, Small Components |

| Shell Molding Machine | Shell Mold Casting | 70 | 150 | Machinery Parts, Valves |

| 3D Printing for Casting | 3D Sand Printing | 10 | 50 | Prototypes, Custom Parts |

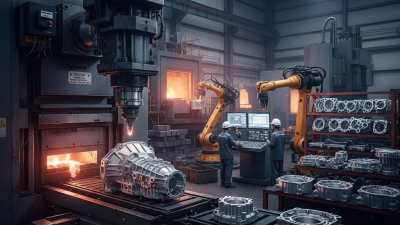

Advancements in automated systems have transformed metal casting processes significantly. These technological innovations enhance productivity and consistency. Automatic pouring systems allow for precise material flow. This reduces human error and improves quality control. As a result, manufacturers can meet larger production demands more efficiently.

Moreover, newer robotics streamlining the casting process minimize waste. Automation can adjust heating and cooling cycles based on real-time data. This adaptability is crucial for optimizing metal properties. However, implementing these systems isn’t without challenges. Initial costs can be high, and training staff requires time.

Some companies still rely on outdated methods. They miss the benefits that automation brings. This reluctance can stem from fear of change or a lack of understanding. To truly excel, companies must embrace these advancements. Investing in automation may lead to significant long-term savings and improved product quality.