+86-13516964051

+86-13516964051

In the ever-evolving landscape of manufacturing, metal casting machines play a crucial role in enhancing production efficiency and achieving significant cost savings. As industries strive to meet increasing demands while optimizing resource utilization, the selection of the right metal casting machine becomes paramount. Dr. Emily Carter, a noted expert in metal manufacturing technology, emphasizes, "Investing in the right metal casting machine is essential not only for productivity but also for the economic sustainability of operations."

This statement encapsulates the industry's shift towards more advanced, automated solutions that can streamline processes and reduce waste. With various types of metal casting machines available today, manufacturers are faced with the challenge of choosing the right equipment that aligns with their operational needs and budget constraints.

From traditional sand casting to modern die casting techniques, understanding the attributes and efficiencies offered by each machine type can empower businesses to make informed decisions. This overview will delve into the top metal casting machine types, exploring their features and potential benefits for efficient production while keeping an eye on cost-saving opportunities.

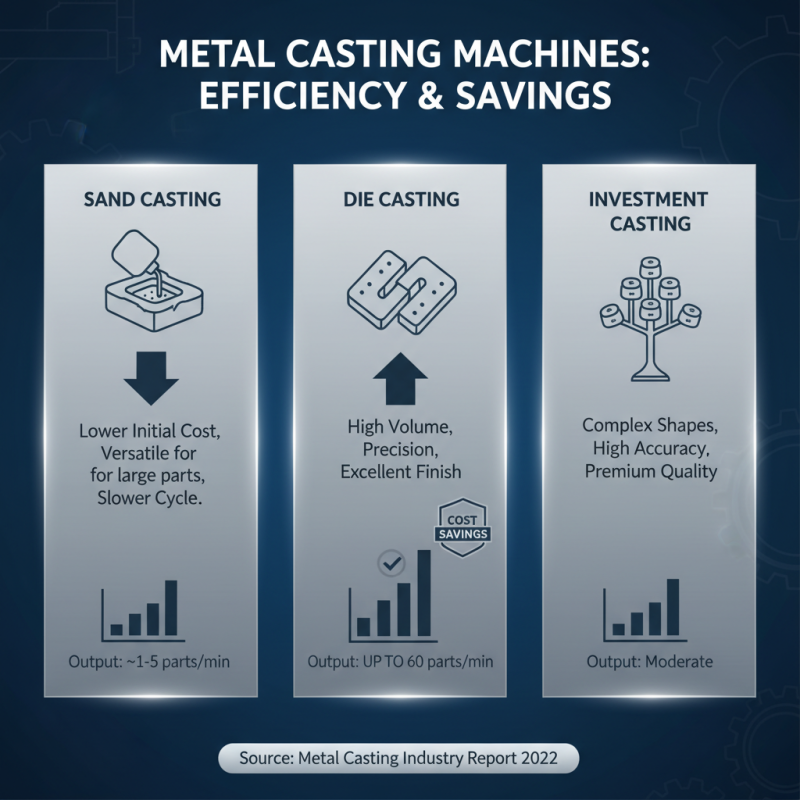

In the realm of metal casting, selecting the right machine is crucial for maximizing production efficiency and achieving substantial cost savings. The primary types of metal casting machines include sand casting, die casting, and investment casting systems. Each offers distinct advantages based on the specific requirements of the production process. For instance, die casting typically provides superior dimensional accuracy and surface finish, making it ideal for high-volume production where precision is critical. According to the Metal Casting Industry Report 2022, die casting can achieve production rates up to 60 parts per minute, significantly enhancing operational efficiency compared to traditional sand casting methods, which generally yield a lower output rate.

Investment casting, on the other hand, is favored for its ability to produce complex geometries with minimal material waste. This process often results in a lower overall cost per unit, especially in small to medium production runs. Industry data suggests that investment casting can save up to 20% in material costs when compared to other methods, making it a preferred choice for industries requiring intricate designs, such as aerospace and medical applications. By analyzing the efficiency metrics of these various casting processes, manufacturers can make informed decisions that not only reduce production time but also optimize material use, ultimately driving down costs while maintaining product integrity.

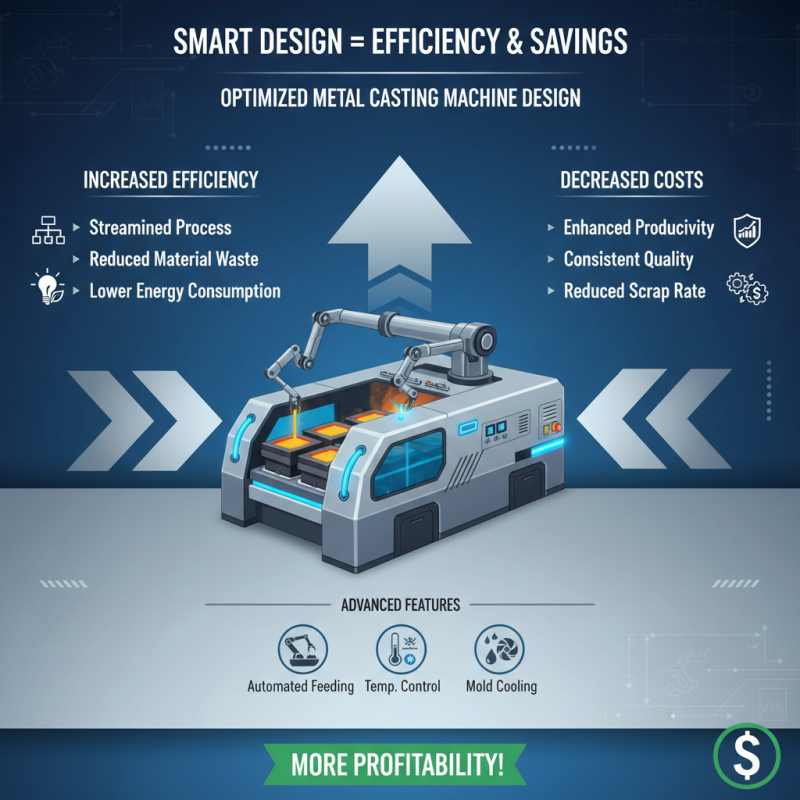

The design of metal casting machines plays a critical role in determining both production efficiency and overall cost savings. A well-engineered machine can streamline the casting process, reduce material waste, and minimize energy consumption. By optimizing the design for speed and precision, manufacturers can significantly enhance productivity. Advanced features such as automated feeding systems, temperature control, and mold cooling mechanisms contribute to maintaining consistent product quality while lowering the risk of defects. This reduction in scrap rate further translates into economic benefits for companies.

Moreover, the integration of new technologies into machine design not only improves operational efficiency but also facilitates easier maintenance and upgrades. Machines that allow for quick changeovers and minimal downtime can be pivotal in adapting to diverse production demands. Additionally, advancements in simulation and modeling software enable manufacturers to analyze and forecast production costs more accurately. By investing in modern machine designs that prioritize efficiency, companies can achieve better resource management, leading to significant long-term savings and improved competitiveness in the market.

When comparing traditional metal casting technologies with advanced methods, it becomes clear that advancements in materials science and engineering have significantly transformed production processes. Traditional casting methods such as sand casting and investment casting often require extensive manual labor and can involve longer lead times. These techniques are time-tested but may not always guarantee consistency in production quality or efficiency. Variability in results, due to factors like temperature control and material handling, can lead to increased waste and operational costs.

In contrast, advanced metal casting technologies leverage innovations like computer numerical control (CNC) machining and additive manufacturing (3D printing). These methods enhance precision and reduce the complexity of designs, enabling manufacturers to produce intricate components with minimal waste. Automation and robotics streamline workflows, allowing for faster production cycles while maintaining high-quality standards. Additionally, advanced casting techniques can adapt to various materials, allowing for greater flexibility in product offerings. This not only leads to direct cost savings but also improves competitiveness in a rapidly evolving market.

This chart compares the production efficiency and cost savings of traditional and advanced metal casting technologies. The data represents the average efficiency percentage and cost savings associated with each method.

When evaluating metal casting machines, several key performance metrics play a critical role in determining their efficiency and cost-effectiveness. The thermal efficiency of the furnace, measured in terms of energy consumption per ton of metal produced, is crucial. According to a 2022 report by the International Journal of Metal Casting, the most efficient machines can reduce energy costs by up to 20%, leading to substantial savings over time. Another significant metric is cycle time, which affects overall productivity. Machines with a reduced cycle time not only enhance throughput but also minimize labor costs associated with long production runs.

It's also essential to consider the yield rate of the casting process. A higher yield rate indicates fewer defects and lower scrap rates, ultimately contributing to cost savings. Industry studies suggest that advanced metal casting technologies can improve yield rates by as much as 15% compared to traditional methods. Additionally, machine maintenance frequency and ease of access for repairs are vital factors in long-term operational costs; machines that require less downtime for maintenance can significantly improve profitability.

Tips: Always review the maintenance logs and user experiences when choosing a metal casting machine. Regular training for operators can also optimize the machine's performance, ensuring that metrics such as energy consumption and cycle times remain competitive. Lastly, consider simulation software that can predict and enhance performance metrics before investing in new equipment.

Recent advancements in metal casting technology have significantly enhanced the efficiency and cost-effectiveness of production processes. One noteworthy development is the rise of automation and robotics in metal casting equipment. According to a report by Grand View Research, the global metal casting market is expected to reach $246 billion by 2030, with automation playing a crucial role in this growth. Automated systems reduce human error, improve product consistency, and allow for faster production cycles, thereby decreasing operational costs while meeting increasing market demands.

Additionally, innovative technologies such as 3D printing and additive manufacturing are redefining traditional metal casting methods. A report published by Research and Markets indicates that the adoption of 3D printing in metal casting could potentially lower costs by up to 30%, as it minimizes material waste and allows for complex designs that were previously challenging to produce. This shift not only streamlines the manufacturing process but also enhances design flexibility, enabling companies to quickly adapt to changing consumer preferences and reduce lead times significantly. As these technologies continue to evolve, they are set to transform the landscape of metal casting, driving both improvements in production efficiency and substantial cost savings.