+86-13516964051

+86-13516964051

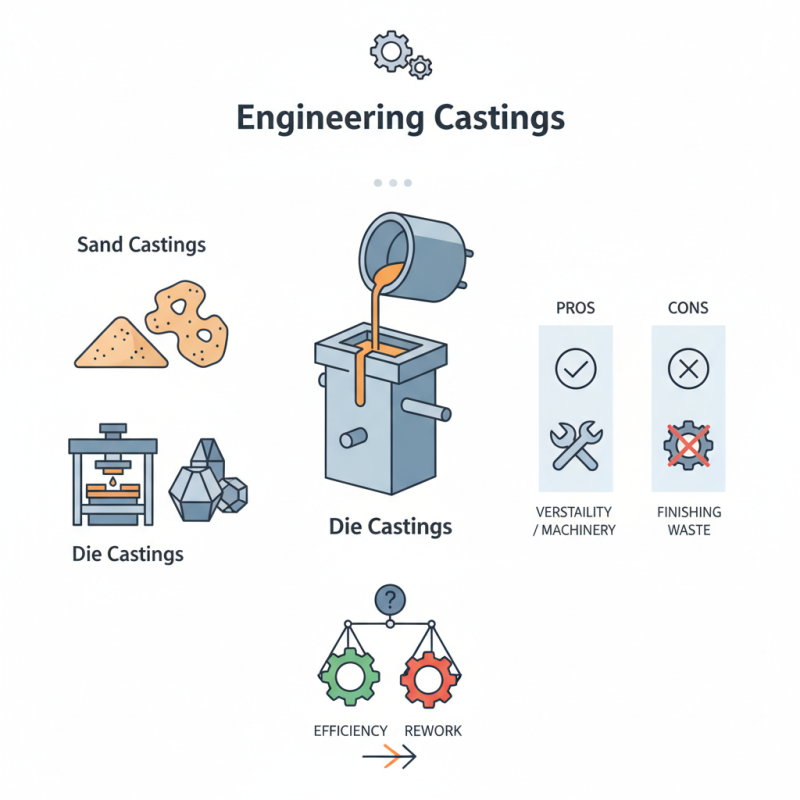

Engineering Castings play a vital role in the manufacturing industry. These castings are produced by pouring molten metal into molds. They are typically used in diverse applications, from machinery to automotive parts.

Many types of Engineering Castings exist, including sand castings and die castings. Each type has unique properties that affect production and application. For instance, sand castings have excellent versatility but may require further finishing.

There are challenges in selecting the right casting type. Each option has its pros and cons, which can complicate decision-making. Understanding these variations is crucial to achieving optimal results in engineering projects. Attention to detail can make or break the quality of the final product. The right choice can lead to greater efficiency, while a poor one may result in waste and rework.

Metal casting processes play a significant role in engineering applications. Different methods cater to varying requirements. The most common types include sand casting, investment casting, and die casting. Each process has unique advantages and challenges. For instance, sand casting is cost-effective, but it may not achieve high precision for intricate designs. According to industry studies, sand casting accounts for approximately 60% of all castings produced globally.

Investment casting, known for its exceptional accuracy, is used for complex geometries. It utilizes a wax pattern that is melted away. Reports indicate that this method achieves tolerance levels of +/- 0.005 inches. However, it is also more expensive due to its intricate setup. Die casting, on the other hand, allows for high-volume production with excellent surface finishes. Yet, it requires significant initial investment for the molds, which can be a barrier for smaller projects.

While these processes offer various benefits, they are not without flaws. For example, defects like porosity can occur in die casting, impacting strength. Additionally, the choice of metal greatly influences outcomes. Aluminum, magnesium, and zinc are common, but each metal behaves differently under the same conditions. Engineers must consider these factors carefully when selecting a casting process for their specific applications.

This chart illustrates the top types of engineering castings based on their frequency of use in industry. Sand casting is the most widely used method, followed by die casting and investment casting. These processes are essential in manufacturing components for various applications.

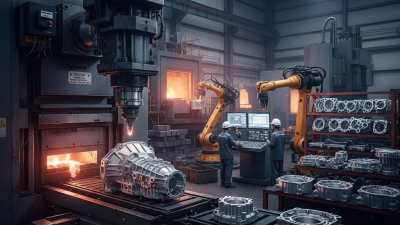

Sand casting is a widely used technique in manufacturing. It involves creating a mold from sand and pouring molten metal into it. This method is favored for its versatility and cost-effectiveness. Sand casting can accommodate various metal alloys, making it suitable for many applications.

One notable advantage of sand casting is its ability to create complex shapes. The sand mold can be easily formed, allowing for intricate designs. This is beneficial in industries such as automotive and aerospace. They often require precise components. However, sand casting may limit the finish quality. Poor surface texture can be a drawback.

Tips: Ensure the mold is compacted well. This helps reduce defects. Additionally, control the cooling rate to avoid cracks. A slow cooling process can improve strength but may lead to warping. Remember, practice makes perfect in mastering this technique.

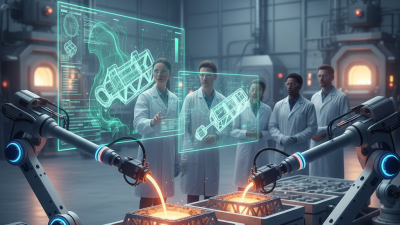

Investment casting is a fascinating process used in engineering. It offers precision and complexity, making it ideal for various industries. According to a report by the Investment Casting Institute, the global investment casting market is projected to reach $25.59 billion by 2025. This growth underlines the increasing demand for high-quality castings.

The process begins with creating a wax pattern. This pattern is coated in a ceramic shell, then heated. The wax melts away, leaving a cavity for molten metal. This technique allows for intricate designs and tight tolerances. Reports indicate that investment castings can achieve dimensional accuracy up to ±0.005 inches. However, the complexity can lead to challenges like higher production costs and longer lead times.

Furthermore, materials used in investment casting can be varied. Alloys like stainless steel, aluminum, and copper are common options. Each material has unique properties impacting performance. Flaws and defects can occasionally occur, requiring additional quality checks. Addressing these imperfections is crucial for meeting industry standards. Investing in new technologies can mitigate some of these challenges. Nonetheless, the intricate nature of investment casting remains a double-edged sword. It embodies both innovation and the risk of potential complications.

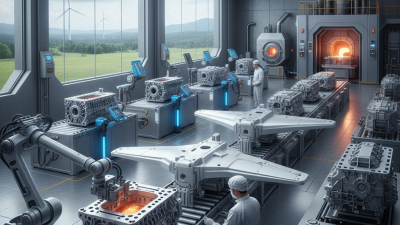

Die casting is a manufacturing process that stands out for its speed and material efficiency. It involves forcing molten metal into a mold cavity under high pressure. This allows for rapid production of complex shapes with remarkable precision. Designers often appreciate its ability to create intricate details that would be hard to achieve with other methods.

However, die casting is not without challenges. The initial setup costs can be high due to the need for precise molds. Achieving uniform wall thickness can also be tricky. If not done correctly, defects can occur, impacting overall product quality. Manufacturers must carefully monitor production parameters to minimize waste and ensure optimal results. In some cases, adjustments are needed during the process to address imperfections.

Material selection plays a crucial role in the die casting process. While aluminum and zinc are commonly used, they may not always be the best choice for every application. It's essential to consider factors like strength, corrosion resistance, and thermal conductivity. Overlooking these aspects can lead to subpar outcomes. Balancing efficiency with quality is a constant challenge for manufacturers in this field.

| Casting Type | Material Used | Production Speed | Material Efficiency | Applications |

|---|---|---|---|---|

| Die Casting | Aluminum, Zinc | High | Excellent | Automotive Parts, Consumer Goods |

| Sand Casting | Iron, Aluminum | Moderate | Good | Heavy Machinery, Engine Components |

| Investment Casting | Stainless Steel, Bronze | Low to Moderate | Very Good | Aerospace, Medical Devices |

| Permanent Mold Casting | Aluminum, Copper | Moderate to High | Good | Home Appliances, Marine Components |

| Centrifugal Casting | Nickel, Iron | Moderate | Excellent | Pipes, Bushings |

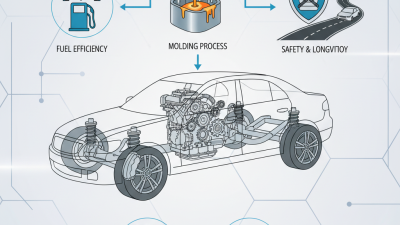

Casting materials play a crucial role in engineering applications. Aluminum, iron, and steel are the most common choices. Each material has unique properties that cater to different requirements.

Aluminum is lightweight and resistant to corrosion. It is popular in aerospace and automotive industries. According to recent industry reports, aluminum castings account for nearly 30% of the total casting market. However, aluminum's strength may not always meet high-stress needs. This limitation can lead to failures in critical applications.

Iron castings, particularly ductile iron, offer excellent strength and wear resistance. They are commonly used in heavy machinery and automotive components. Reports estimate that iron castings represent over 40% of market share. Yet, these castings can be brittle. Choosing iron often requires careful consideration of design to prevent breakage.

Steel castings provide high strength and toughness, making them suitable for demanding applications. They are widely used in structural components. Although steel castings make up about 25% of the market, their weight can be a downside. Therefore, engineers must balance weight and performance when selecting steel. Each material has benefits and drawbacks that require thoughtful evaluation in engineering projects.