+86-13516964051

+86-13516964051

In the manufacturing industry, "Dies Aluminium" plays a crucial role. These aluminum dies are essential for precision and efficiency. According to Dr. James Whitaker, a leading expert in this field, "Aluminium dies transform ideas into tangible products quickly." His insight highlights the importance of adoption in various manufacturing sectors.

Aluminium dies are versatile tools used across multiple applications. They allow for high-quality production of complex parts. However, not all manufacturers fully take advantage of their benefits. Understanding the limitations and potential issues is necessary. The process can be costly if not managed properly. Many companies face challenges in maintaining die durability and performance.

The impact of "Dies Aluminium" is evident in industries like automotive and aerospace. These fields demand precision at high volumes. However, the production process can pose difficulties. Some manufacturers struggle to optimize their workflows. Reflecting on these challenges can lead to better practices and innovations.

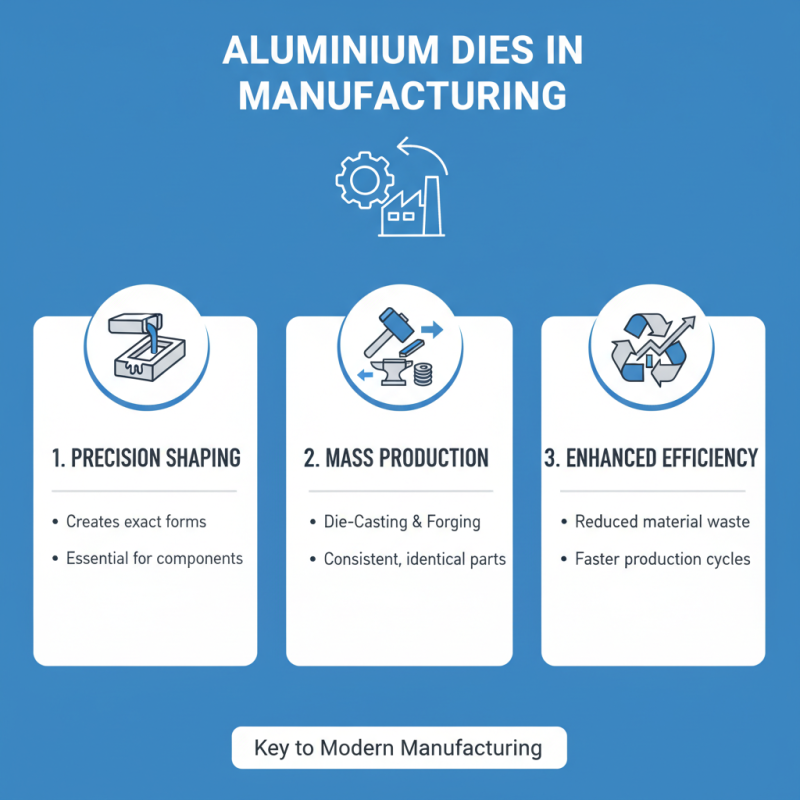

Aluminium dies play a crucial role in the manufacturing industry. They are essential for creating precise shapes and forms. Manufacturers use them in various processes like die-casting and forging. This allows for mass production of components with minimal waste. Hence, the efficiency of production increases significantly.

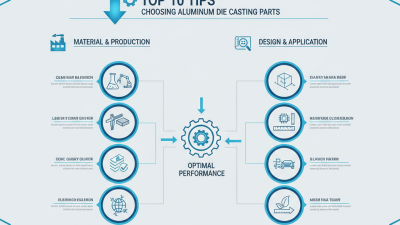

Tips for choosing aluminium dies: Always consider the specific application before selecting a die model. Keep in mind the complexity of the design. Sometimes, simpler dies may yield better results.

Additionally, it's important to maintain aluminium dies regularly. Wear and tear can lead to defects in the finished products. Regular checks can help avoid costly mistakes. The need to constantly innovate remains a challenge. Manufacturers must adapt to new technologies while using aluminium dies effectively.

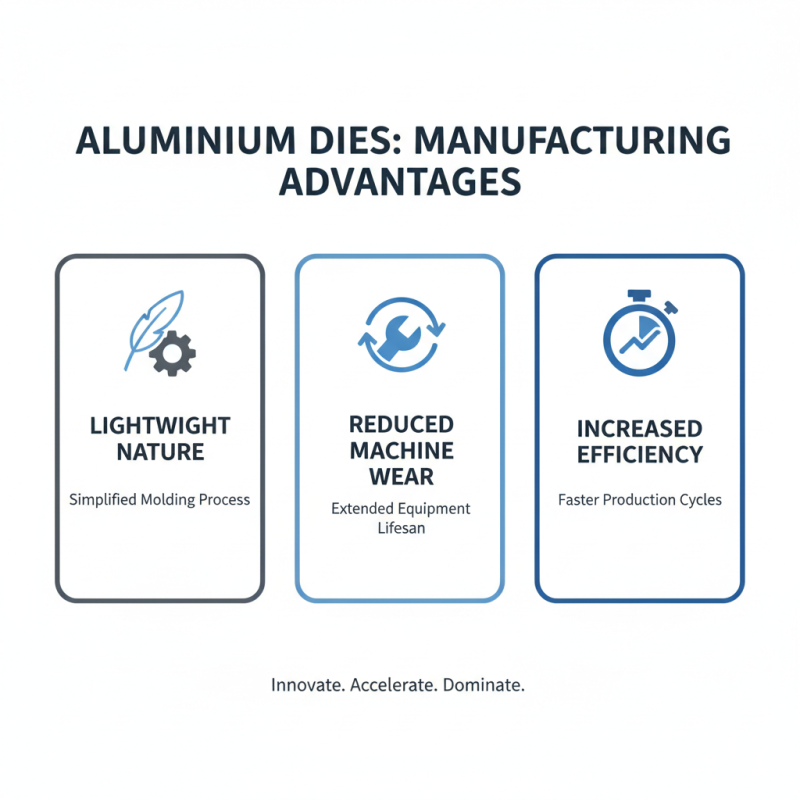

Aluminium dies are gaining popularity in the manufacturing industry. They offer significant advantages over traditional materials. One key benefit is their lightweight nature. This characteristic simplifies the molding process. It also reduces wear on machinery, leading to longer equipment life.

Aluminium has excellent thermal conductivity. This property allows for faster cooling and heating cycles. Quick cycles can increase overall production rates. Efficiency is essential in a competitive market. However, companies must not overlook potential drawbacks. Aluminium may not be as durable as steel in certain applications.

Tips for using aluminium dies effectively: Always consider the intended production volume. For low to medium runs, aluminium dies excel. Yet, for high-volume tasks, evaluate if they are the best long-term solution. Additionally, keep die maintenance consistent. Regular checks can prevent costly delays. Remember that while aluminium can be cost-effective, it is crucial to assess each project individually.

Aluminium dies play a crucial role in various manufacturing sectors. Their lightweight nature makes them ideal for high-volume production. In automotive manufacturing, aluminium dies are used to create components like engine parts and body panels. This helps reduce vehicle weight, improving fuel efficiency.

In the electronics industry, manufacturers utilize aluminium dies for precision parts. These components can include casings and brackets. The durability of aluminium ensures product longevity, which is vital in technology applications. A practical tip is to consider the thermal conductivity of aluminium. It aids in efficient heat dissipation for electronic devices.

Packaging also benefits from aluminium dies. They can create custom shapes for container designs, enhancing product appeal. However, it's essential to ensure the quality of dies. Improperly designed dies can lead to waste and increased costs. Regular maintenance on dies is crucial. This minimizes errors during production and maximizes efficiency.

Aluminium dies play a crucial role in the manufacturing industry. The process of creating these dies involves several steps. First, designers create a digital model using CAD software. This model outlines the die's exact specifications. Next, manufacturers use CNC machines to shape the aluminium. This machining process ensures precision. The result is a die that fits the intended production requirements accurately.

After the die is crafted, it is tested rigorously. This testing phase identifies any flaws or adjustments needed. Sometimes, even minor errors can lead to significant production issues. Thus, thorough testing is essential. In production, these aluminium dies are used with a variety of materials. They can produce items ranging from automotive parts to everyday household goods.

Tips: Always prioritize maintenance of the dies. Regular cleaning and inspection can prolong their lifespan. Being mindful of wear can help catch problems early. Also, investing in quality materials during die production often pays off in the long run. Choose wisely to avoid costly mistakes. Quality assurance at every step is vital for success in manufacturing.

| Use Case | Description | Benefits |

|---|---|---|

| Die Casting | Process for producing parts by forcing molten metal into a mold. | High precision, complex shapes, and rapid production. |

| Extrusion | Shaping material by forcing it through a die. | Consistent cross-sections and high efficiency. |

| Stamping | Process of using dies to cut or shape metal sheets. | Quick production and low waste material. |

| Forging | Shaping metal using localized compressive forces. | Increased strength and durability of parts. |

| Machining | Removing material using rotary tools to achieve precise dimensions. | High accuracy and finish quality. |

| Molding | Creating parts by pouring liquid material into molds. | Versatile and allows complex shapes. |

| Injection Molding | Forcing material into a mold to create plastic parts. | High efficiency and repeatability. |

| Assembly Fixtures | Tools designed to hold components securely during assembly. | Improves precision and efficiency. |

| Prototype Development | Creating samples to test design concepts. | Faster product development cycle. |

| End-Use Products | Final products created directly from aluminum dies. | High-quality finished goods ready for market. |

The future of aluminium die manufacturing is bright, fueled by innovation and technological advancement. One significant trend is the increase in automation. Precision machining and robotic systems streamline the die-making process. This reduces production time and enhances consistency. However, not all manufacturers adopt these technologies. Some rely on traditional methods, which may limit efficiency.

Sustainability is another focal point. More companies are exploring eco-friendly materials and processes. Recycling aluminium brings considerable savings and environmental benefits. Yet, many still overlook these practices. There is a need for industry-wide change to embrace sustainable methods.

Finally, additive manufacturing is making waves in this sector. 3D printing of die components allows for more complex shapes. This technology can significantly reduce material waste. Still, challenges in integration remain. Companies must balance innovation with current production capabilities. Embracing these trends will be imperative for staying competitive.