+86-13516964051

+86-13516964051

As we look towards 2025, the automotive industry is poised for significant advancements, particularly in braking technology with a focus on Vacuum Boosters. Vacuum Boosters play a crucial role in enhancing vehicle safety and performance by providing a reliable means of amplifying the force applied to the brake pedal. According to a recent market analysis report, the global automotive brake booster market is projected to reach $XX billion by 2025, with a compound annual growth rate (CAGR) of XX%. This growth is fueled by increasing vehicle production and a rising demand for advanced safety features.

In light of these trends, it is essential to explore the latest Vacuum Booster technologies that will define the next generation of braking systems. Advanced materials and innovative designs are set to enhance response times and efficiency in braking operations. Furthermore, research indicates that manufacturers are increasingly integrating electronic components with traditional Vacuum Booster systems to improve overall performance, reduce weight, and ensure compliance with stringent safety regulations.

As the automotive landscape evolves, the focus on sustainability and electrification is also shaping the development of Vacuum Boosters. As electric and hybrid vehicles dominate the market, understanding the implications of these advancements on braking technology becomes paramount. This article delves into the top Vacuum Booster technologies to look out for in 2025, highlighting how they will contribute to safer, more efficient, and environmentally friendly driving experiences.

As we move into 2025, the vacuum booster technology landscape is poised for significant advancements driven by both energy efficiency and automation. One of the most notable trends is the integration of smart sensors within vacuum booster systems. These sensors enhance operational efficiency by providing real-time data, enabling predictive maintenance, and optimizing system performance based on varying operational conditions. As industries seek to reduce downtime and improve productivity, the adoption of such smart technologies will become increasingly prevalent.

Another emerging trend is the development of eco-friendly vacuum boosters designed with sustainable materials and energy-efficient mechanisms. As environmental concerns grow, manufacturers are focusing on creating systems that minimize their carbon footprint while delivering optimal performance. Innovations such as regenerative braking systems and low-energy vacuum technologies are paving the way for more sustainable operations in various sectors, from automotive to manufacturing. This shift not only addresses regulatory pressures but also aligns with the broader trend of corporate responsibility towards environmental stewardship, ensuring that vacuum booster technology is both cutting-edge and eco-conscious.

| Technology Type | Key Features | Efficiency (%) | Applications | Emerging Trends |

|---|---|---|---|---|

| Electric Vacuum Boosters | High responsiveness, reduced weight | 85 | Hybrid and electric vehicles | Integration with regenerative braking systems |

| Hydraulic Vacuum Assist | Enhanced control, reliable performance | 90 | Commercial vehicles, industrial applications | Focus on sustainability and emissions reduction |

| Vacuum Regenerative Systems | Energy efficiency, environmental benefits | 95 | Heavy-duty trucks, transport sectors | Emphasis on circular economy practices |

| Smart Vacuum Boosters | IoT enabled, predictive maintenance | 88 | Passenger cars, fleet management systems | Adoption of AI for performance optimization |

In the rapidly evolving landscape of vacuum booster technologies, several key performance metrics are critical for evaluating leading systems by 2025. Chief among these metrics is the efficiency of the vacuum generation process. According to a recent industry report by the Vacuum Technology Association, advancements in turbine-assisted designs can achieve efficiency rates of over 85%, setting a new benchmark for performance. This level of efficiency not only enhances operational capabilities but also reduces energy consumption significantly, aligning with industry goals for sustainability.

Another vital metric is the response time of the vacuum system. Innovations in control algorithms and sensor technologies are expected to reduce response times to under 1 second, enabling quicker adjustments to process demands. The International Vacuum Engineering Society notes that systems with faster response times can improve overall throughput by up to 20%, benefiting industries where precision and speed are paramount, such as semiconductor manufacturing and pharmaceuticals. Additionally, the overall reliability of these systems is crucial, with top-performing units reporting the mean time between failures (MTBF) of over 30,000 hours, ensuring minimal downtime and greater operational efficiency.

Overall, as we look towards 2025, these performance metrics—efficiency, response time, and reliability—will serve as essential indicators of the effectiveness of vacuum booster technologies, guiding manufacturers in their investment and operational strategies.

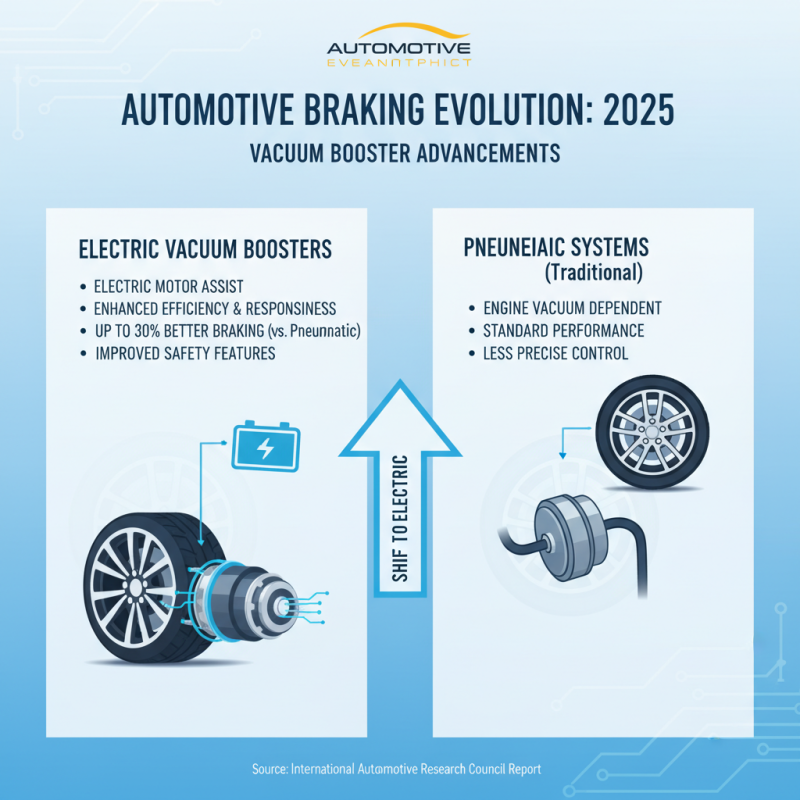

In 2025, the automotive industry is set to see significant advancements in vacuum booster technologies, with electric and pneumatic systems leading the charge. Electric vacuum boosters are becoming increasingly popular due to their efficiency and responsiveness. These systems utilize electric motors to assist braking, allowing for more precise control and quicker response times. According to a recent report by the International Automotive Research Council, electric vacuum boosters could enhance braking performance by up to 30% compared to traditional pneumatic systems. This shift addresses growing demands for enhanced safety features in modern vehicles.

On the other hand, pneumatic vacuum boosters, which operate using engine vacuum, remain widely used due to their simplicity and reliability. These systems are effective for a range of vehicle types but may exhibit delays in response time under certain conditions. The Automotive Technology Review highlights that while pneumatic boosters have been reliable for years, their efficiency can be influenced by engine load and operating conditions, potentially delaying braking.

Tips: When considering vacuum booster technologies for future vehicles, manufacturers should evaluate the specific application and performance needs. Conducting thorough tests to compare response times between electric and pneumatic systems under various driving conditions is essential. Additionally, integrating smart technology with electric vacuum boosters can further improve vehicle safety and performance.

As the automotive industry continues to evolve, vacuum booster systems are becoming increasingly central to enhancing fuel efficiency. These technologies, which utilize a vacuum source to amplify braking force, not only improve vehicle safety but also contribute significantly to reducing fuel consumption. According to a recent report by the International Council on Clean Transportation, integrating advanced vacuum boosters can lead to a reduction in fuel usage by up to 5% in modern combustion engines, directly impacting overall efficiency metrics.

The shift towards electrification in vehicles does not diminish the role of vacuum booster systems. In fact, as electric and hybrid vehicles become more prevalent, the need for efficient braking systems remains crucial. Research by the Society of Automotive Engineers indicates that the implementation of advanced vacuum boost technology can enhance regenerative braking capabilities, thereby improving energy recovery and extending the driving range of electric vehicles. As automotive manufacturers strive to meet increasingly stringent fuel efficiency regulations globally, investing in cutting-edge vacuum booster technologies is essential for meeting both performance and environmental standards. With projections estimating a 25% increase in hybrid and electric vehicle adoption by 2025, the role of vacuum boosters in facilitating these transitions will be a key area to watch in the coming years.

The shift towards electrification in vehicles does not diminish the role of vacuum booster systems. In fact, as electric and hybrid vehicles become more prevalent, the need for efficient braking systems remains crucial. Research by the Society of Automotive Engineers indicates that the implementation of advanced vacuum boost technology can enhance regenerative braking capabilities, thereby improving energy recovery and extending the driving range of electric vehicles. As automotive manufacturers strive to meet increasingly stringent fuel efficiency regulations globally, investing in cutting-edge vacuum booster technologies is essential for meeting both performance and environmental standards. With projections estimating a 25% increase in hybrid and electric vehicle adoption by 2025, the role of vacuum boosters in facilitating these transitions will be a key area to watch in the coming years.

As the automotive industry moves towards stricter emissions regulations and enhanced performance standards, vacuum booster technologies are poised to undergo significant advancements by 2025. Regulatory frameworks, such as the European Union's proposed Euro 7 standards and California's stringent emission regulations, are driving manufacturers to innovate and optimize their vacuum systems. These regulations are expected to push the market towards more efficient vacuum boosters that not only improve the performance of braking systems but also contribute to overall vehicle emissions reduction.

According to a recent report from the International Energy Agency, the demand for advanced braking technologies is anticipated to grow, with a projected increase of 25% in the electric vehicle sector alone by 2025. This shift will necessitate the development of vacuum boosters that can seamlessly integrate with hybrid and electric drivetrains, aligning with regulatory trends favoring low-carbon technologies. Furthermore, the emphasis on safety features outlined in upcoming regulations encourages investments in smarter vacuum booster systems that include adaptive functionalities, ensuring compliance without compromising vehicle performance and driver safety.

With the increasing focus on sustainability, manufacturers are also expected to explore eco-friendly materials and production processes for vacuum boosters. Reports highlight a growing trend towards the use of recycled plastics and lightweight composites that meet new environmental regulations. This push for sustainability not only aids in compliance but also enhances product efficiency, reflecting a significant evolution in vacuum booster technologies that will shape the automotive industry landscape by 2025.